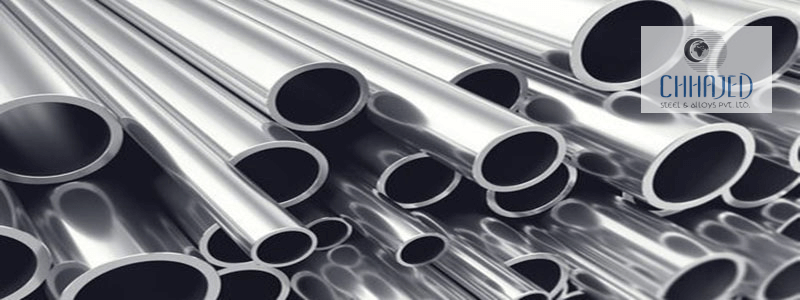

410 Stainless Steel Welded Rectangular Pipes Manufacturers

410 pipe material has good corrosion resistance along with high strength and hardness and is used for the application which involves heat resistance, mild corrosion and high strength. It is a general purpose martensitic stainless steel which contains 11.5% chromium and this provide properties of good corrosion resistance. It obtains maximum heat and corrosion resistance through hardening. However the corrosion resistance can be further enhanced by the process of hardening, tempering and polishing. Tempering and quenching can harden alloy 410. 410 Seamless Pipes process annealing can be carried at temperatures ranging from 650 to 760 °C and air-cooled. It can be fully annealed at temperature ranging between 815 – 900 °C, followed by air cooling and slow furnace.

SA 312 tp 410 at temperatures up to 650 °C Grade 410 has good scaling resistance. It is resistant to steam, hot gases, mild acids and alkalies, food, air and fresh water. However it tends to reduce its mechanical properties at temperature ranging from 400 – 580 °C. Stainless Steel 410 Pipe is welded by using all conventional welding techniques but it should be pre heated at 150 – 260 °C followed by post weld annealing treatment to mitigate cracking. SS 410 welding rods are recommended for tempering and post-hardening. ASTM A312 tp 410 its heavy sections need to be oil quenched. Tempering process is been done to enhance the mechanical properties and hardness. It can be hardened at temperature ranging between 925 – 1010 °C, followed by oil or air quenching.