Agitator For Mixing

SUNKAIER mixing equipment division have experienced experts and engineers to develop suitable mixing technology for specific applications.

Mixing operation process is one of the most common operations in chemical, petrochemical, pharmaceutical and food industries. Its purpose is to make two or more media can achieve the maximum degree of contact, so as to complete the required mixing, mass transfer, heat transfer or reaction process in a predetermined time. The basic function of stirring process is mixing. Whether it is the stirring mechanism, the concrete structure design of agitator and the calculation of stirring power are closely related to the properties of the medium involved in the stirring process. Therefore, in engineering design, stirring types can be basically divided into four categories: homogeneous liquid-liquid mixing, heterogeneous liquid-liquid dispersion, gas-liquid dispersion and mixing, and solid-liquid suspension mixing.

SUNKAIER mixing equipment division delivers full line to service different industries including:

Mixing Agitators

Light Duty Agitator SK100

Static Mixer

Mid Duty Agitator SK400

Inline Mixer

Reactor Agitator SK500

High Shear Agitator

Magnetic Agitator SK1000

Pharma Agitator

Side-Entry Agitator SK800

Cosmetic Agitator

Bottom Entry Agitator

Chemical Agitator

Top Entry Agitator

Polymer Agitator

Vertical Agitator

Petrochemical Agitator

Coaxial Agitator SK700

Biofuel Agitator

Coating Agitator

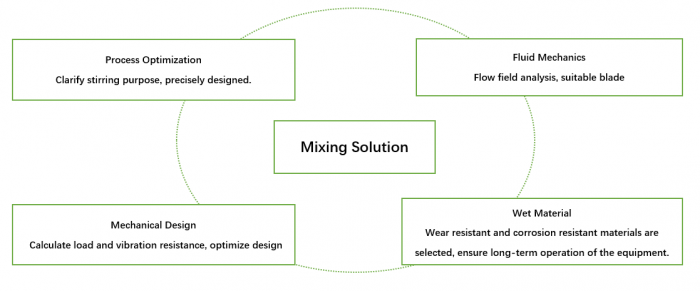

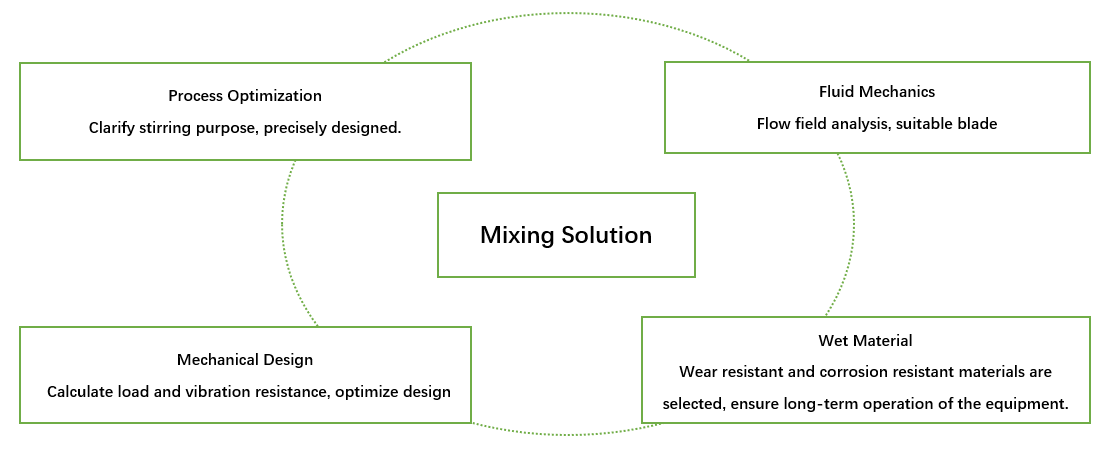

Sunkaier mixing equipment include: impeller selection, chemical design, detailed mechanical design, economic analysis optimization and mechanical drawing, etc. System covers the entire range of design almost all the functions of mixing system design, from the Newton fluid to non-newtonian fluid, from low to high viscosity, from ordinary propeller type to the special propeller type, from the miscibility fluid blender to gas liquid solid three phase system, including homogeneous liquid mixing, heterogeneous liquid-liquid dispersion, solid-liquid suspension, gas-liquid dispersion, strengthening heat transfer, strengthening mass transfer, reaction, etc. Can be used in chemical, paper, food, petroleum, medicine and other industries.