Aluminum Extrusion Accessories of Different Specifications for Medical Devices

Aluminum Extrusion Accessories of Different Specifications for Medical Devices

1. Aluminum extrusion parts are an important component of medical equipment

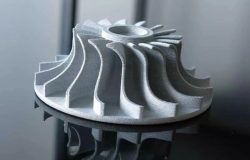

The production of aluminum extrusion parts will use an extrusion process. This process uses the original form of aluminum to heat the billet to a specified temperature. At this temperature, the aluminum becomes soft and ductile, and then it is transferred to the press container. The press presses the aluminum billet through the container by applying greater pressure and squeezes it through the final shape of the die. Then, the extruded parts pass through various stations, where they can be cooled, stretched and cut to the required length.

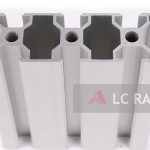

Aluminum extrusion parts are one of the important materials for building medical aluminum frame structures. When assembling various medical aluminum products, you must also use the matching aluminum extrusion parts. It can be seen that aluminum extrusion parts are useful for medical aluminum products. It has a great influence, so when choosing aluminum extrusion parts for medical devices, it is necessary to put forward higher requirements for its quality.

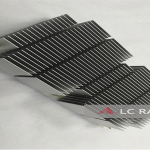

2. Aluminum extrusion parts of different specifications for medical devices

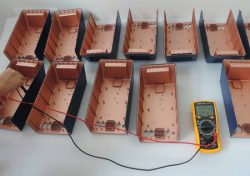

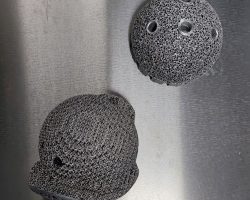

Aluminum extrusion parts for medical devices are classified according to specifications. Generally, 1010 aluminum extrusion, 1515 aluminum extrusion, 3030 aluminum extrusion, 3060 aluminum extrusion, 4020 aluminum extrusion, 4040 aluminum extrusion and 4080 aluminum extrusion can be used.

There are many commonly used medical aluminum accessories, and the specifications and materials of each accessory are different, and the connection methods are also various. Medical aluminum is light in weight, and there are various types of medical aluminum accessories, which can basically meet the needs of users. Common medical aluminum accessories include bolts, nuts, corner pieces, connectors, end connection plates, spacer connection blocks, and elastic buckles. For example, Medtronic’s medical trolley uses aluminum extrusion parts.

3. Medical aluminum production process

1) Casting

Casting is the first process of aluminum machining. Electrical appliance profiles are mainly used in various fields such as bus bars, overhead wires, conductors, electrical components, refrigerators, air conditioners, and cables.

The important processes are:

Ingredients: According to the specific alloy grades to be produced, calculate the increase of various alloy components, and match various original materials reasonably.

Smelting: The prepared raw materials are added to the melting furnace according to the process requirements for melting, and the slag and gas in the melt are effectively removed by degassing and slagging refining methods.

Casting: Under a certain casting process, the molten aluminum is cooled and casted into round casting rods of various specifications through a deep well casting system.

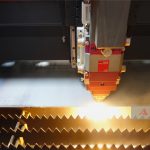

2) Extrusion

Extrusion is a means of forming profiles. First, design and manufacture a mold according to the profile product section, and use an extruder to extrude the heated round cast rod from the mold. Commonly used 4080 aluminum profiles require an air-cooling quenching process and subsequent artificial aging process during extrusion to achieve heat treatment strengthening. Different specifications of heat-treatable and strengthened alloys have different heat treatment systems.

3) Coloring

Oxidation: The extruded medical aluminum has a weak surface corrosion resistance and must be treated by anodizing to increase the corrosion resistance, wear resistance and aesthetic degree of the aluminum.

Under the guidance of high quality standards, the aluminum extrusion technology of LC Rapid carries out strict quality control over the entire manufacturing process. We conduct regular tests and verifications at all stages of manufacturing to ensure that we deliver excellent quality products every time.