Application of CNC Machining in Medical Device Field

Application of CNC Machining in Medical Device Field

With the advancement of CNC processing technology, the manufacturing of medical devices is becoming more and more humanized. For nearly half a century, many precision machining manufacturers have been providing fast, accurate and reasonably priced medical equipment, tools and parts. In an industry with the most stringent requirements and the shortest turnaround time, a large number of medical devices rely on our correct, efficient and economical CNC processing to be applied.

1. Application of CNC machining

From MRI and CT scanning components to cardiovascular and orthopedic implants, companies that provide the most precise medical machining on the market today are inseparable. Unlike other types of precision mechanical parts processing plants, which leave a certain margin of error in manufacturing, medical CNC processing means that it is 100% responsible for precise processing of each component.

Automated machining, like automated sheet metal fabrication, has appeared since the 1960s, and many of the modern materials used in our precision machine parts processing plants are cutting-edge – just like the revolutionary use of the parts we produce. Our experience and craftsmanship are outstanding, because we have been in the field of CNC machining medical equipment for many years.

When you place an order with us, customers will get the best combination in all aspects, from customer service and CNC machining experts to modern equipment and timely work processes.

In fact, if today’s top doctors and medical technicians do not have the precision equipment they rely on, modern medical breakthroughs are impossible to achieve.

2. Market development of CNC machining

As patients increasingly seek science and medical technology to improve their quality of life, CNC machining of medical devices is both exciting and demanding. Of course, our precision machinery CNC processing plant has long realized that whether customers want to obtain a test prototype for precision parts processing, or need a new product line to produce for sales, the key to saling medical equipment is to find a trustworthy manufacturer under the present competitive situation.

Because our precision machinery parts processing plant has a keen understanding of customers’ efforts to bring life-changing medical equipment to the market, we must pay attention to details in every CNC machining order so that these customers can get more returns. Accuracy and reliability are closely related to our CNC machining services.

Therefore, when we manufacture medical equipment parts, it will inspire the trust and confidence of client companies and medical professionals who rely on the product in their daily work.

Because today’s medical equipment parts are usually very small, the business of our precision mechanical parts CNC processing plant is to provide customers with high-quality precision micro-machining. As a supplier with many years of machining experience, LC RAPID MANUFACTURING Co., Ltd. keeps mastering the technology and services related to non-standard parts processing in the medical industry.

3. Medical CNC precision machining

The development of CNC precision machining industry has also driven many related industries such as consumer electronics, medical equipment and other fields. The development of these industries has not only brought orders to the CNC precision machinery parts processing industry, but also promoted the development of CNC precision processing plants. Of course, the development of CNC precision machinery processing industry and the upgrading of technology have also provided better CNC machining parts services for related industries, and objectively promoted the upgrading of related industries.

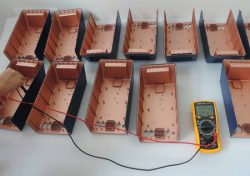

The medical device industry and CNC precision machinery processing industry are highly related industries that promote each other and develop in coordination. There are many medical equipment R&D companies and many CNC processing manufacturers. Medical equipment companies are often interested in product research and development, and considering a large number of mold opening risks, they will find some regular CNC processing manufacturers to cooperate, and require some CNC precision machining models to be produced first, which can be assembled and used, and the effect is verified first. This will test the raw material molding technology of CNC processing manufacturers.

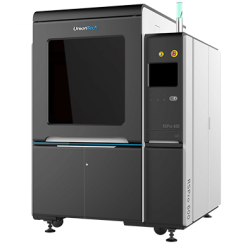

Many small medical device model factories are definitely not up to standard in accuracy and do not meet customer needs. So they found our CNC processing plant to handle this difficult situation well, thanks to the provision of multiple five-axis processing machines. The accuracy can reach +0.01mm, which can meet the requirements of customers on 3D drawings. If you are worried that the use environment will affect the product, the professional project manager of our technical department will negotiate with the customer to come up with a plan, and then select the use of raw materials.

If your medical device products want to be used in the exhibition and want to produce exquisite appearance, our CNC precision machining service can also meet your requirements. Our CNC processing factory can process it 24 hours a day, and it can be shipped quickly within one week. We introduce a third-party CTO to guide the appearance process and conduct a three-dimensional accuracy test for free. Like other small medical device model factories, there will not be so many configurations. We look forward to cooperating with you.