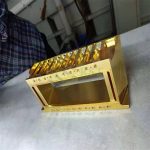

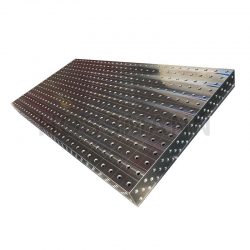

Barrel electroplating equipment for zinc copper nickel

Barrel plating is the electroplating of workpieces inside a drum. During plating, the current conduction between the workpiece and the anode, the renewal of the solution inside and outside the barrel and the discharge of the exhaust gas all need to pass through these small holes.

Barrel zinc plating machine features:

• Anti-corrosion & Anti-oxidation: Barrel zinc plating equipment provides a durable shield against corrosion and oxidation, ensuring your workpieces stand the test of time.

• Supply conductive & insulating coatings: Whether you need conductive or insulating coatings, this equipment delivers precisely what your projects demand.

• Improve wear resistance: Strengthen the lifespan of your workpieces with enhanced wear resistance, preventing the effects of daily wear and tear.

• Enhancement of reflectivity: Achieve impeccable, reflective finishes that elevate the visual appeal of your products, leaving a lasting impression.

• Increase corrosion resistance: Protect your materials against the harshest elements, increasing their corrosion resistance and longevity.

• Enhancement of aesthetics: Small barrel plating equipment elevates the visual appeal of your workpieces, making them truly stand out with a pristine finish.

• Process requirements: The barrel zinc plating equipment for sale is versatile and adaptable, catering to various plating process requirements with utmost precision.