BMC/SMC Molded Products

SMC, BMC thermosetting plastic products are produced by SMC and BMC plastic molding process.

Types of BMC/SMC Molded Products

BMC/SMC Motor

SMC/BMC plastic edging motor change the traditional material of iron and aluminum to reduces the process but seals more.

Servo Motor

Plastic-Envelop Motor

Over Moulding Products

High-Voltage Electrical Products

Mainly refers to switch boxes, electric control boxes, circuit breakers, fuses and transformers, etc.

High Voltage Circuit Breaker

High Voltage Fuse Box

High Voltage Switch Box

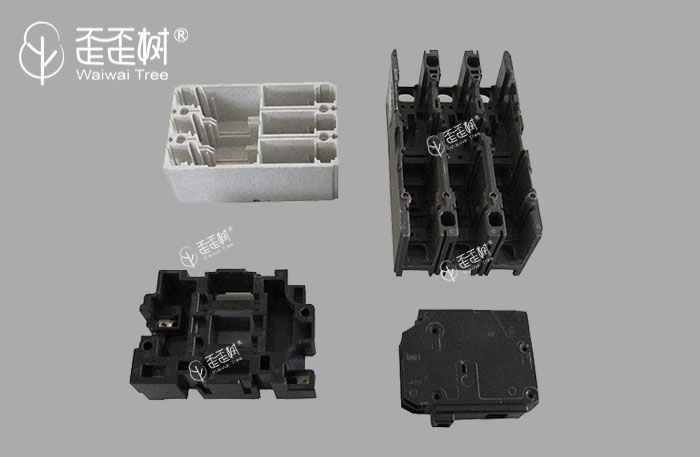

Low-Voltage Electrical Products

Low-Voltage Electrical Products are not much different from high-voltage electrical products but it is a low-voltage equipment with long life.

Low Voltage Circuit Breaker

Low Voltage Fuse Box

Low Voltage Switch Box

SMC Automotive

Auto Parts And Accessories are much more lighter than normal products of the same sizes made of steel and aluminum.

Car Bumper

Battery Box Enclosure

Car Light

Insulated Shell

Insulated Shell can endure for more than 30 years with an external airflow passage in the tank for adjusting inside temperature.

High Voltage Box

Outdoor Cabinet

Electrical Box

What is SMC Plastic?

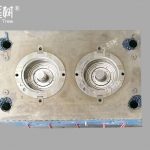

SMC/BMC is one of thermosetting plastics, and SMC/BMC thermosetting plastics are thermosetting molding compounds made of unsaturated polyester resin as matrix resin. The main components of SMC/BMC thermosetting plastics include resins, thickeners, low shrinkage additives, fillers, internal mold release agents, colorants, stabilizers, and the like. It is first formulated into a resin paste and then used to impregnate or blend with a reinforcing material to form a preformed molding material. According to the preforming process and the shape of the obtained preformed material, it can be divided into SMC thermosetting plastic and BMC thermosetting plastic or DMC integral molding plastic. SMC/BMC thermosetting plastics are easy to form, have low molding shrinkage, high dimensional accuracy and good processing performance. SMC/BMC thermoset plastic products have excellent electrical insulation, heat resistance, flame retardancy and good mechanical strength. SMC, BMC thermosetting plastic products are widely used in electrical, construction, civil appliances, daily necessities and other industries to process a variety of insulation, structural parts, decorative parts and daily necessities.

We provide you with SMC thermoset molding and BMC thermoset molding.

About BMC/SMC Products

Zhejiang Aobang has long been committed to SMC/BMC molded parts and BMC injection parts forming processing services and SMC/BMC mold design and manufacturing. The company’s strong technical strength and strong technical research and development capabilities can provide customers with SMC / BMC composite integrated solutions. The company produces various types of SMC/BMC molds, and can design and adjust the formula according to the customer’s specific requirements to meet the relevant process and use requirements. It can suppress products with various properties such as flame retardant, electrical, anticorrosive, high strength and high toughness. Can be widely used in highways, automobiles, electrical, electrical, chemical, communications, railways and other fields. SMC/BMC thermoset plastic products are characterized by high mechanical properties, precise dimensions and good electrical properties. It can meet the special requirements of different products of customers, and also provide professional technical support and services for customers with different process requirements.