Clean Way To Remove Impurities – High Pressure Water Blasting Equipment

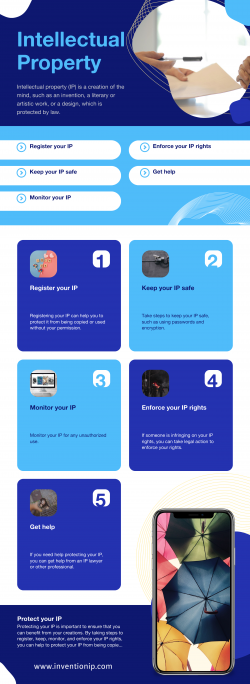

Pressure Water Blasting is a technique that has been in play since 1870. This technique uses water and soap to enable degreasing with synchronous blasting to eliminate dust and hazardous material or waste(asbestos or other impurities). It doesn’t pose any danger to surfaces and structures, resulting in effective decontamination. This is done by High Pressure Water Blasting Equipment which varies in size and pressure.

Pressure Water Blasting forcibly propels abrasive material against a surface under high pressure in order to achieve the following:

- Smoothing of a rough surface

- Roughening of a smooth surface

- Shaping of a surface

- Removal of surface contaminants

The Pressure Water Blastingprocess can be done using all traditional blasting formats such as walk-in booths, hand cabinets, automated production machinery, and total loss portable blasting units. The speed of the process depends upon the requirement. The surface which has been cleaned using the process is not damaged as water acts as a buffer. Thus, there are two advantages of abrasive water blasting, it decreases media breakdown rate, and second, it prevents foreign material from sticking to the surface. The level of cleanliness of water blasting is way better than dry blasting because of which it is preferred before coating or bonding operations too.

Types of Wet Blasting Techniques

There are a number of wet blasting techniques presently available for choice. Few of them are

- Wet Abrasive Blasting

- High-pressure water blasting

- High-pressure water and abrasive blasting

- Air and water abrasive blasting

The choice of blasting method depends upon the requirement and according to the application.

Pressure Water Blasting Equipments Details

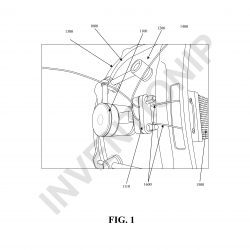

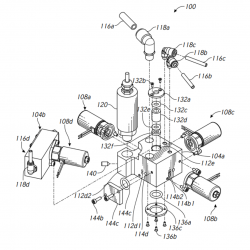

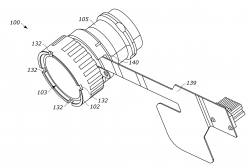

The wet blast devices are mostly of cabinet-mounted type that can be easily modified. You can take-off conveyors, auxiliary strippers, and wash-rinse dry stations. The blasted device is usually composed of the following parts:

- Vertical wheel

- Horizontal plane turntable

- Shuttle with rail/car extensions

- Chain/belt conveyors

- Self-contained turning mechanisms for shafts and tubular parts

- Combination tumbling-cabinet machines

How Does Pressure Water Blasting Work?

Pressure Water Blasting equipment involves the propulsion of a slurry towards a surface with the help of a high-velocity air propulsion system. The slurry is finely abrasive and mixed in chemically treated water. involves high-velocity compressed air propulsion of a slurry towards a surface. The compressed air is sent into a vessel at a pressure equal to that fed to a blast hose. The pressure is equalized so as to enable the abrasive mixture to feed into an airline. A full flow valve is located between a hopper and mixing chamber which is used to control the flow of abrasives.

Applications of Wet Abrasive Blasting

The applications of wet abrasive blasting are as follows:

- Burr removal from substrates

- Preparation of surface for hard chrome coatings, bonding composites, bonding coatings, bonding composites, and time and other tool coatings.

- Aviation engine rebuilding

- Etch glass for decorative or functional purposes

- Peen surfaces for a bright, and clean appearance

- Automotive overhaul and engine rebuilding

- Clean plastic injection molds

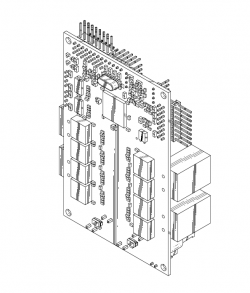

- Hole cleaning for printed circuit boards

Benefits of Wet Pressure Water Blasting

The list of benefits of Pressure Water Blasting is long but key benefits of wet Water Blasting are listed below:

- Extremely fine media can be used

- Media impregnation into the substrate is not possible

- Deeply cleans irregular surfaces

- Eliminates the need for hand-sanding

- Eliminates the need to use toxic chemicals

- Reduces dust

- Closed cabinet recycles media/slurry

- No heat warping with thin parts

- The final finish is appealing with a satin feel

- Provides an excellent surface for plating

- Provides an excellent surface for bonding

- Holds tight tolerances

Contact Us and get the equipment at an affordable price from Aquamiser.