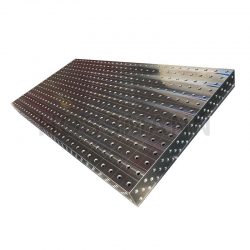

CNC Machining For Precision Aluminum Parts

Aluminium CNC Machining Features

Material Selection: We meticulously choose the right aluminium alloy based on the specific needs of the application, considering factors like strength, corrosion resistance, and thermal conductivity.

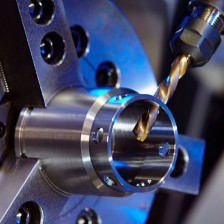

Precision Tooling: Utilizing high-quality cutting tools such as tungsten carbide and high-speed steel ensures durability and extends tool life, contributing to the precision of our machining.

Proper Cutting Speeds and Feeds: We strike a balance between cutting speed and feed rate to prevent tool wear and enhance surface finish.

Cooling and Lubrication: Employing coolants and cutting fluids is essential for heat dispersion and chip evacuation, maintaining consistent temperatures during the machining process.

Rigorous Quality Control: Implementing stringent quality control measures ensures that our final products meet precise specifications and avoid costly rework.