Definition and Raw Materials of Flat Belt

Flat Belt Definition

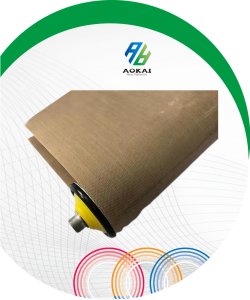

Flat belt is a kind of power transmission belt with a flat surface, usually with uniform texture on both sides, used in pulley drive system. In history, flat belts usually use pulleys to transmit power to other parts of the machine, thereby driving the machine’s operation.

Nowadays, they are commonly used as part of power transmission devices. There is a kind of belt drive that uses a flat belt, which is the thing we talk about. It operates through a drive and a pulley. The drive speed of a flat rubber belt can even exceed 3000 feet per minute. Specifically, the power is generated under the operation of the drive, and is transmitted from one shaft to the other through the belt, that is, when the two shafts are separated by a certain distance, a flat belt is required to transmit the power.

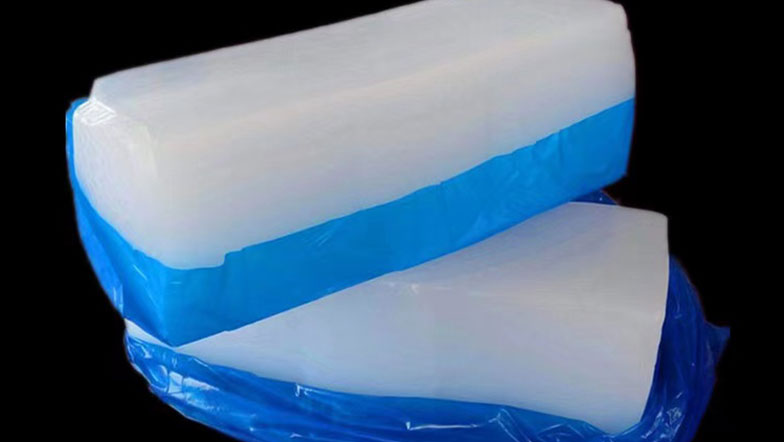

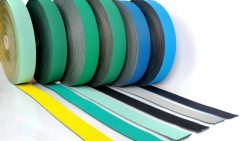

Flat Belt Materials

Long ago, leather was one of the original materials for making flat drive belts. Nowadays, due to the toughness and durability of nylon and other synthetic materials, new flat belt materials are constantly being used. In addition, rubber, metal and other materials are gradually being used in the production of flat belts uses. Some of them have been reinforced with particularly strong materials, which can help users eliminate concerns about structural wear rates. However, no matter how strong the material is, there will be more or less wear during actual use, and sometimes the flat rubber belt will be twisted due to operating errors or long use years, which will seriously delay the production time and affect the normal operation of users. Therefore, it is recommended that users regularly check and replace the flat belt for machinery.