Eaton Char-Lynn Motor – Motor Block Rupture: 7 Items

What are the causes of motor block rupture? Eaton Char-lynn Motor details:

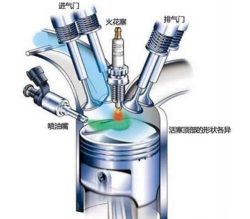

1. Intake of the motor cylinder (combustion chamber) causes the motor link to break. When the vehicle is driving on a road with water on the road, the motor draws water into the cylinder. The water initially entering the cylinder quickly forms hydrated gas under the action of the high temperature of the cylinder, so that the cylinder cannot form a combustible mixture. As the amount of water increases, water accumulates on the top of the piston, reducing the effective volume of the chamber, increasing the compression resistance, and increasing the pressure transmitted by the piston to the connecting rod. When the amount of water reaches a certain level, the compression stroke actually becomes a compression of water, and the pressure on the connecting rod is sharply increased, so that bending deformation occurs until breaking, and even the motor block is broken. Since the motor cylinder water intake and motor speed determine the pressure on the connecting rod, not all of the vehicle motor cylinders will immediately break after the water inlet.

2. Abnormal motor fuel injection system causes the connecting rod to break. This causes the situation to be caused by the continuous injection of fuel from a certain cylinder of the motor. Often there will be difficulties in starting up, idling, smoky exhaust pipes, and reduced power. After dismantling, it can be judged by observing the combustion condition of each cylinder. For the cylinders with more fuel injection, the cylinder and the cylinder head will be blacker than the other cylinders because the combustible mixture is thicker than other cylinders. At the same time, the injector and its injection control circuit can be further checked.

3. The connecting rod and the crankshaft lock cause the motor connecting rod to break. This situation is generally caused by poor motor lubrication and can be judged by checking the internal wear of the motor.

4. The link itself has problems. This situation can generally be determined by the chemical composition analysis of the connecting rod material and the hardness test, the metallographic structure inspection, the scanning electron microscope fracture analysis and the like. The possible causes are low-stress fatigue fracture caused by quenching micro-cracks. Pearlite + flakes, oversized non-metallic inclusions, massive ferrite, etc. in the structure cause the mechanical properties and fatigue life of the connecting rod to decrease.

5. Improper maintenance operation. For example, when the soaking method is used, the cleaning liquid is not cleaned, resulting in the top cylinder when the motor is restarted; for the motor equipped with the variable inlet system, if the cleaning system is free of cleaning, if the cleaning agent flow rate and the motor speed Mismatching may result in excessive cleaning agent accumulating in the intake manifold. At high speeds, the long intake port changes to a short intake port, and the cleaning agent in the intake manifold instantaneously draws into the combustion chamber to cause the top cylinder.

6. After the rollover, the oil in the oil sump flows into the air filter, the intake manifold and the intake port through the common pipeline of the crankcase. After the motor is started, a large amount of oil is sucked into the combustion chamber. During the compression process, the oil is not compressible. The pressure on the top of the piston is increased, the connecting rod is bent and deformed, and the user travels for a long time. At high speed, the connecting rod suddenly has fatigue fracture. You can check whether there is a rollover accident record to check whether the air filter is organic oil or not. The abnormality of the ring height trace is judged.

7. Damage to the crankcase system results in an oil top cylinder. For motors equipped with a variable intake system, if the diaphragm crankcase venting valve ruptures, a large amount of oil may be continuously drawn into the intake manifold and gradually accumulate, and the long intake port becomes short-term during high-speed driving. In the air passage, the oil in the intake manifold is instantaneously sucked into the combustion chamber to cause the top cylinder.

https://www.xjetl.com