Eaton Char-Lynn Motor , Two Kinds Of Material Analysis Of Car Motor

Whether it is a brochure for a new car that consumers see in their daily lives, or a technical analysis by the relevant staff of a car media such as Cang Ge, when they participate in a test drive and product briefing, they will cast aluminum Motors. As a technical highlight to introduce, is this cast aluminum Motor really upgraded compared to a cast iron Motor? Why is the low profile cast aluminum and the top match cast iron? Which material is better in the Motor? The Eaton Char-lynn Motor analyzes the quality of the two materials of the Motor: cast aluminum and cast iron

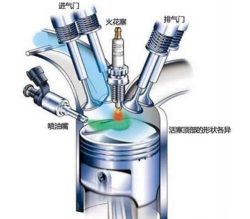

The all-aluminum Motor mentioned here means that the cylinder head and the cylinder block are both made of aluminum alloy. The cylinder head is made of aluminum alloy, and the cylinder is a cast iron Motor. It is still called a cast iron Motor. Because the weight of the cylinder head itself is not large, the car manufacturer is keen on it not because of its light weight, but because of it. Has good heat dissipation performance. Here, we can also know that the all-aluminum Motor is indeed superior to the cast iron Motor in terms of material and heat dissipation.

The physical properties of iron and aluminum are not the same. The heat load of the cast iron cylinder is only stronger, and the potential of the cast iron is greater in terms of the Motor’s rising power. For example, a 1.3-liter displacement cast iron Motor can output more than 70 kW, while a cast-aluminum Motor can only reach 60 kW. It is understood that the 1.5-liter displacement cast iron Motor can reach the power of the 2.0-liter displacement Motor through turbocharged technology, and the cast-aluminum cylinder Motor is difficult to reach this requirement. All aluminum Motors are used in very few premium cars and very few regular cars.

In actual use, the so-called advantages of the so-called advanced technology and good heat dissipation of the all-aluminum Motor are not reflected, but the damage is difficult to repair. For example, when repairing the Motor, the torque of the tightening screw is slightly larger, which may cause damage to the thread, which is difficult to repair. There are also some all-aluminum Motors that pursue high technology and do not have a cylinder liner. They only use a high-voltage arc wire on the cylinder to spray a layer of iron. If the Motor is overheated, it can neither be smashed nor set. Cylinder liners can only be scrapped, which will greatly increase maintenance costs. At the same time, the all-aluminum Motor does not allow the random brush computer to increase the Motor power, otherwise it will cause the Motor to burst. The cast iron Motor will not have such a problem, it is very convenient to repair, whether it is a cylinder or a cylinder liner, it is very easy and the cost is not high. In addition, the same Motor can be made into multiple versions of high and low power. The power and torque of the Motor can be changed by changing the boost value and the control unit’s program, and the hardware part of the Motor does not need to be changed.

However, the all-aluminum Motor is not perfect. On the one hand, due to the light specific gravity of aluminum, the structural strength per unit volume of aluminum is less than that of cast iron, so the volume of the aluminum cylinder is usually larger than that of cast iron. It is difficult to achieve the compactness and small size of the cast iron cylinder block. On the other hand, aluminum is easily chemically reacted with water generated during combustion, and therefore, corrosion resistance is far less than that of cast iron cylinders, especially for supercharged Motors where temperature and pressure are higher. At the same time, due to the volume, when the Motor volume requirement of the automobile is small, it is difficult to achieve the strength of the cast iron cylinder body by using the aluminum cylinder. Furthermore, the physical properties of cast iron and aluminum determine that the coefficient of friction of cast iron cylinders is superior to that of all-aluminum Motors, so cast iron Motors are also superior to all-aluminum Motors in terms of service life.

According to the research surface, the fuel consumption can be reduced by 6%-8% for every 10% reduction of the car’s own weight, which is why some luxury brands focus on promoting lightweight aluminum and aluminum Motors. If you want to maintain the same output as the cast iron Motor, you need to solve the problem of tolerance and corrosion resistance of the all-aluminum Motor. Now the mainstream is generally used in two ways. One is to add another layer of cylinder in the cylinder. The so-called high temperature and high pressure tolerance is borne by the cylinder liner, and an additional layer of protection. This method has high requirements for the processing and assembly process, and the cost of the cylinder liner is quite expensive. The other is Additional metal elements are added to provide aluminum tolerance through alloying, no matter which cost is not low, which is why the current household car Motor still uses cast iron cylinders. In fact, the weight of the car does not come down, even if the Motor is placed on an all-aluminum Motor, the impact on fuel consumption is actually not large, so if you want to buy an ordinary family car, then the choice of cast iron Motor is actually no problem, there is no need to be some cars. The propaganda of the enterprise is around。

https://www.xjetl.com