Explosion Proof Connector Elbows SE Series

Advantages

Class I Division 1,Group A,B,C,D

Zone 1, Zone 2

Class II Division 1,Group E,F,G

Zone 21, Zone 22

Class III

Type 4X,IP66

Ex d IIC Gb

Max. M115x1.5 or NPT4″

Ex tb IIIC Db IP66

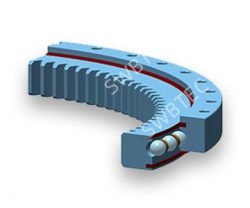

For narrow space, conduit corner where no enough space to reach to operate and conduit layout turning where direction change requests, SE series explosion proof connector can be used as explosion proof elbow to change the conduit direction to fit in explosion proof lighting, explosion proof enclosure, explosion proof panel and explosion proof junction box., this flame proof connector also could be used as 3 4 emt pull elbow and hazardous area plug where flammable gas and dust produce to meet class 1 division 1 conduit requirements and class 1 division 2 conduit requirements.

Features

Explosion Proof Connector SE Series

01

90°type structure to change the conduit direction

Explosion Proof Electrical Connectors

02

45°type structure to bend the conduit conveniently

Explosion Proof Cable Connectors

03

M male thread/ M male thread, M male thread/ F female thread, F female thread/ F female thread

Selection Table

Explosion Proof Connector SE Series

Data Sheet

Explosion Proof Connector SE Series

Compliaces

IEC StandardIEC60079-0, IEC60079-1, IEC60079-7, IEC60079-31Ex d IIC GbEx tb IIIC Db IP66Zone 1, Zone 2Zone 21, Zone 22

EU StandardEN60079-0, EN60079-1, EN60079-7, EN60079-31II 2 G Ex d IIC GbII 2 D Ex tb IIIC Db IP66Zone 1, Zone 2Zone 21, Zone 22

NEC & CEC StandardClass I, Div.1, Group A, B, C, DClass II, Div.1, Group E, F, GClass III

UL StandardUL844, UL1598, UL1598A

CSA StandardCSA C22.2 No.137

Material

Nickel Plated Brass / 304 Stainless Steel / 316 Stainless Steel

IP Grade

Wet Locations, Type 4X, IP66

Ambient Temperature

-40℃~ +100℃ / -40°F ~ +212°F