HEAT RESISTANT SPRAY PAINT (300℃/600℃)

7CF® Heat Resistant Spray Paint (300℃) is an organosilicone resin base high temperature resistant aerosol paint, which is made of special organosilicone resin, heat resistant pigments, and additives combined with advanced production technology. It has the characteristics of flexible and simple operation, good spraying atomization, and a high ejection rate.

Self-dry paint film at room temperature solidifies as the temperature rises. After being baked at 200 ℃ for 2 hours, paint film reaches optimum performance. It can achieve a long-term heat resistance performance of 300℃ while maintaining paint film intactness. It does not fade and peels off. It is an ideal high-temperature aerosol paint for consumers.

7CF® Heat Resistant Spray Paint (600℃) is an organosilicone aerosol paint withstanding high temperature up to 600 degrees centigrade. Paint film conducts self-dry 30 minutes after application. After being baked at 200℃ for 2 hours, paint film reaches optimum performance. It can achieve a long-term heat resistance performance of 600℃ while maintaining paint film intactness.

WHERE TO BUY

High Heat Resistance-1200 BLACK

High Heat Resistance-1200 BLACKHigh Heat Resistance-1300 SILVER

For more colors, please download the 7CF color card, welcome to customize the colors you need.

7cf-color-card

TDS & SDS

HEAT RESISTANT SPRAY PAINT (300℃/600℃) FEATURES & BENEFITS

Heat Resistance up to 300℃/600℃

Waterproof, Weatherable and Resistant to Moisture

Excellent protection against rust, impact, UV, etc

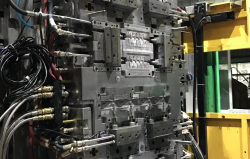

Ideal for use on auto’s or motor’s exhaust pipe or wherever a high-temperature coating is needed

HEAT RESISTANT SPRAY PAINT (300℃/600℃) FEATURES & BENEFITS

HEAT RESISTANT SPRAY PAINT (300℃/600℃) APPLICATIONS

Suitable for all kinds of fields with high temperature, like chimneys, BBQ, oven, heat pipe, auto’s or motors exhaust pipe and other high-temperature parts.

DIRECTION

Read entire label before using this product.

1

Thoroughly remove dirt, grease, oil, and water on the surface to be painted.

2

Fill the recessed part with Poly-Putty Base and smooth it.

3

Shake can vigorously for two minutes after the mixing ball begins to rattle, until the paint is fully mixed and uniform.

4

Hold can upright 20-30cm from surface and use your index finger to press down the nozzle to spray in a steady back and forth motion.

5

Apply in thin multiple layers, thin layers applied every 2 minutes are always better than one thick layer.

6

If the spray is not finished at one time, turn the bottle upside down and press down the nozzle for 3 seconds to clean out the valve and prevent plugging.

PHYSICAL & CHEMICAL PROPERTIES

Item

Standard

Paint film color and appearance

Film flat and smooth, no mechanical impurities, accord with the confirmed sample.

Surface dry 20℃/h

≤ 0.5

Finger press dry (Bake at 200℃/h) /h

≤ 2

Flexibility

≤3 mm

Impact resistance

≥ 35 cm

Adhesion/level

≤2

Water resistance

(immersed in distilled water for 24 hours, taken out and placed for observation after 2 hours)

The appearance of the paint film remains unchanged

Gasoline resistance (immersed in RH-75 gasoline for 24 hours)

the paint film does not foam or soften

Heat resistance [(600±20)℃, after 6h baking]

the paint film is intact, basically not discolouring, in line with the standard model

Spraying rate

≥97%

Shelf Life

Three Years

PACKAGING SPECIFICATIONS

ITEM NO.

Container size

Optional sizes

A-S-010

10oz(283g)

8oz(226g), 9oz(255g)