How Do I Choose an Annular Cutters?

An annular cutter is a special drill used to drill through steel. Like a hole saw for wood, the annular cutter only cuts the outer edge of the hole.

It can produce precise burr-free holes to close tolerances without pre-drilling or step drilling. It can drill larger holes with less force and time than a standard twist drill bit. As it rotates, the tool produces chips from the outer cutting edge, and after cutting the hole, the “chips” (round pieces of steel in the center of the tool) fall off.

Why use annular cutters?

Annular cutters offer superior holemaking capabilities. They cut faster, last longer, produce better hole finish, true round holes with very tight tolerances, and can be resharpened and drilled with less power and torque.

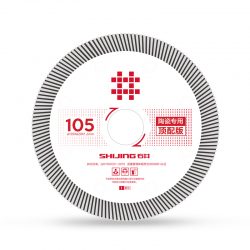

TCT Annular Cutters

How do I choose a annular cutters?

When drilling, it is important to know the type of material being drilled, as there are many options for selecting annular cutters.

Material type

When looking for an annular cutter, the type of material to be drilled is a key factor in knowing which tool to choose. Before purchasing an annular cutter, know the material you will be drilling. They range from mild steel such as A36 and aluminum to armor plate and stainless steel varieties. Depending on chemical composition, even most of today’s structural steels are harder and more flexible. AR (wear-resistant) steels are becoming more popular and can be difficult to drill. If you don’t know your material, find out.

Types of annular cutters

Gone are the days of grabbing a magnetic drill and plowing twist drills through steel with blue chips flying. Annular cutters are the standard for holemaking with magnetic drills. These tools make the job easier, more efficient and save stores money.

Annular cutters are the standard for holemaking with magnetic drills. These cutters make the job easier, more efficient and save stores money.

HSS Annular Cutters

Tooth geometry

Another factor in the annular cutter equation is the tooth geometry. Cutting multiple plates at once will not use the same tooth angles as when cutting a single plate. Companies use different geometries and features to help ensure maximum success.

Coating

And don’t forget about coatings. Annular cutter manufacturers can apply a variety of different coatings to increase tool life in harder materials. Remember, you get what you pay for. Also, look for annular cutters that can be resharpened. This will save you more money in the long run.

Other important factors

After choosing the right annular cutter, there are other factors that can help you achieve greater success.

1. Always use coolant, and use the machine’s through-spindle coolant whenever possible. Cutting tools love coolant.

2. Use good, steady feed pressure. Make sure you are pulling a good chip.

3. Aim for close to the recommended RPM for the tool and material. the life of your tool will thank you.

4. Use a sharp annular cutter, as sharp edges just cut better.

5. Make sure the arbor and mounting system holding the tool is strong and secure, or you may quickly dull or break the tool.

6. Always use a guide pin. The slug must be ejected.The source is from here.

![AIDA64 Extreme/Engineer 7.00.6700 Cracked + License Key [Updated]](https://socialsocial.social/btabcloud/uploads/2024/01/download-jpeg-17062552564p8lc-250x250.jpg)