How Many Layers Of Plywood Is Good

Panel furniture, refers to the main body of man-made panels, using hardware or round bar tenon joint assembly from the flat type of furniture. Panel furniture and solid wood furniture have their own advantages and disadvantages, but as more and more consumers demand, making the boundary between board furniture and solid wood furniture is increasingly blurred. Thus, the 2017 update of GB/T 3324 “General Technical Conditions for Wooden Furniture” has a new furniture classification: panel wood furniture.

Board and wood furniture, refers to the frame are made of solid wood, the board or frame inside the board using veneer man-made panels made of wood furniture. It can be seen that, with the increasing scarcity of wood resources, the use of man-made panels in furniture will become more and more widespread. The custom ply furniture industry commonly used artificial boards are plywood, blockboard, medium fiberboard, particleboard, etc. They also have their own characteristics. There is no best, only the most appropriate.

Plywood Description: How Many Layers in Plywood

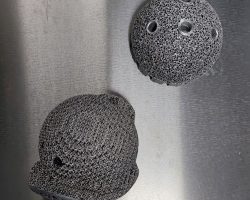

Plywood is a man-made board made of logs that have been rotary cut or planed into veneers, then formed into an odd number of layers according to the principle that the adjacent layers are perpendicular in fiber direction (one horizontal and one vertical), and then glued and hot pressed. Generally speaking, the surface veneer (surface board) of plywood is made of relatively good species, while the middle veneer (core board) is made of common species.

In order to improve the anisotropy of natural wood as much as possible and make the plywood wood properties uniform and stable in shape, the plywood needs to comply with two basic principles in structure: one is symmetry, and the other is that the adjacent layers of veneer fibers are perpendicular to each other. The principle of symmetry is to require the veneer on both sides of the symmetrical center plane of the plywood, whether it is wood properties, veneer thickness, number of layers, fiber direction, moisture content, etc. should be symmetrical with each other; in the same plywood, you can use the same species and thickness of the veneer, you can also use different species and thickness of the veneer, but the symmetrical veneer, species, and thickness must be the same. About how many layers in plywood , plywood usually have an odd number of layers such as 3, 5, and 7 layers.

Plywood Characteristics: the Layers of Plywood

Plywood custom furniture has the following characteristics: the board area is large and easy to process; the thickness of layers of plywood board is small, but the strength and hardness are not bad, the impact resistance and durability are good, and the nailing force perpendicular to the board surface is high; natural wood is characterized by easy cracking in the direction of the grain, while plywood is a staggering laminated wood, so there is no need to worry about the cracking that may occur when nailing or screwing; due to the balanced structural characteristics of plywood, the forces of adjacent veneers can offset each other, thus reducing warping and deformation caused by anisotropy and dry shrinkage and wet expansion.

Plywood Furniture Company: Good Plywood for Furniture

Therefore, in panel furniture, DIMEI high quality plywood for furniture is often made into large-area parts, such as doors, panels, backs, side panels, and top panels of cabinet furniture, as well as seat surfaces of chairs and drawer bottoms. The surface of plywood can be finished to make various decorative plywoods, such as thin wood, paper, plastic, metal, and other finishing materials on its surface. The plywood veneered with planed teak and beech thin wood can be used in the middle and high-end furniture parts instead of precious wood.

With the total thickness of the plywood fixed, is it better to have more or fewer plies of plywood? We believe that more layers of plywood mean better improvement of wood anisotropy. In addition, the more layers, the smaller the thickness of the veneer, which places higher demands on the wood species, as well as the planing and cutting process; at the same time, there are more variables in the quality of the small thickness of the veneer when gluing. Therefore, more layers of plywood requires higher technology and materials, and the quality and price will be higher accordingly.

https://www.dimeihome.com/how-many-layers-of-plywood-is-good.html