HPMC Tile Adhesive

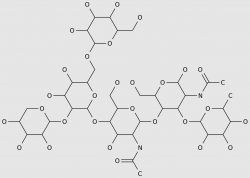

HPMC is a highly pure cotton cellulose as raw material, under alkaline conditions by special etherification and preparation. White or whitish powder.

Product DescriptionHPMC for tile adhesive

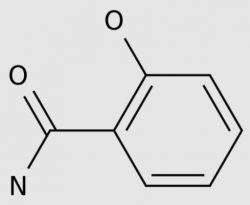

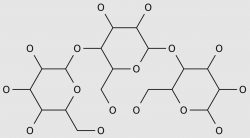

Hydroxypropyl methylcellulose (HPMC) is a non-ionic cellulose prepared from natural polymer materials through a series of chemical processes. Containing almost all properties of methyl cellulose (MC), it is your first choice for the production of high-quality building materials additives. When HPMC for tile adhesive, it has water repellent and thickening cellulose ether, which greatly increases the flexibility of the tile adhesive, improves the stress, and increases the flexibility.

Physical characteristics

Drying Method

Drying

Certification

ISO9001

Substrate

Ceramic

Components

Film Forming Matter

Formation Mechanism

Conversion Type

Model No.

HPMC

pH

5-8

Bulk Density

0.40-0.70 g/cm3

Ash Content

3-10%

Particle Size

98.5% Passes Through 100 Mesh

Viscosity

60000-200000

Trademark

YiBang

Transport Package

25kg/Bag

Specification

viscosity between 5-200000 cps

Origin

China

HS Code

391239

Product Details

HPMC is a odorless, non-toxic, and tasteless white powder. It dissolves in cold water to form a clear and viscous solution. It has good water retention, thickening, emulsification, film formation, suspension, adsorption, gelation, surface activity and protective colloid. And so on. Products are widely used in product systems such as water-based paint, putty powder for interior and exterior walls, and thermal insulation mortar series.

The amount of HPMC tile adhesive is 0.2~0.3% of dry mortar.According to the ratio of powder: water = 1: 0.25-0.3.After stirring evenlyAdjust the position of the tiles within the allowed operating time, and wait until the adhesive is completely dry (filling can be carried out after about 24 hours, and heavy objects should be prevented from pressing on the surface of the tiles within 24 hours).

Product Parameters

Product name

HPMC

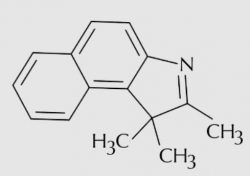

content of methoxy

28.0-30.0 27.0-30.0 19.0-24.0

content of hydroxypropyl

7.0-12.0 4.0-7.5 4.0-12.0

temperature of gelation

58-64 62-68 70-90

moisture

≤5%

Ash

≤1%

PH Value

4-8

Apperance

Whie powder

Fitness

80-100 list

Viscosity

300-200,000 It can be custmized

Re HPMC increased with methoxy content reduce, the gel point water solubility and surface activity also declined. Depends on customers’ situation

Application of HPMC for tile adhesive

1. Building construction

•Used as a water-retaining agent and retarder in mortar to make it have good pumpability.

•Used as a binder in gypsum, gypsum materials, putty powder or other building materials to improve its workability and extend operating time.

•Used as a sizing agent for tile, marble and plastic decoration, reducing the amount of cement.

•HPMC water retention performance can prevent too fast drying and cracking after spraying, and enhance the strength after hardening.

2. Ceramic industry

• It is widely used as a binder in the ceramic production industry.

3. Coating industry

• Used as a thickener, dispersant and stabilizer in the coating industry.

• It has good compatibility in water or organic solvents.

• Used as paint remover/paint remover.

4. Ink printing

•Used as a thickener, dispersant and stabilizer in the ink industry.

• It has good compatibility in water or organic solvents.

5. Plastic

•Used as mold release agent, softener, lubricant.

6. Polyvinyl chloride (PVC)

•Used as a dispersant in the production of PVC, and the main auxiliary agent for PVC suspension polymerization

7. Other:

•Widely used in leather, paper products, textile, fruit and vegetable preservation and other industries.

Summary: HPMC for tile adhesive is widely used in gypsum plaster, tile bonding mortar, joint fillers, thin coatings, wall putty powder, diamond grouting additives, external wall insulation systems/external insulation and finishing systems, etc.