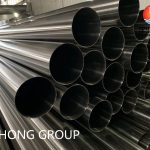

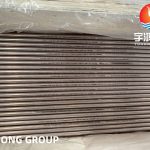

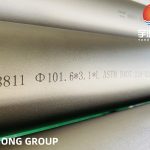

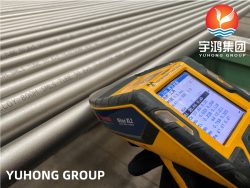

INCOLOY 800/N08800 NICKEL ALLOY PIPE/TUBE

Incoloy 800 is a solid solution strengthened alloy of nickel, chromium, and iron with small additions of aluminum and titanium. ASTM B163 B407 ASME SB163 SB407 N08800 Incoloy 800 Seamless Tubing is particularly useful for high-temperature equipment in the petrochemical industry because the alloy doesn’t form the embrittling sigma phase after long time of exposure at 1200°F (649°C). Excellent resistance to chloride stress-corrosion cracking is another important feature of alloy 800 tube/pipe.

INCOLOY 800/N08800 NICKEL ALLOY PIPE/TUBE EQUIVALENT SPECIFICATION

Country

Body

Grade

USA

UNS

N08800

France

AFTER

Z8NC 32.21

GB

BS

NA 15

Germany

DIN

1.4876

INCOLOY 800 PIPE/TUBE PHYSICAL PROPERTIES

Properties

Metric Units

Density

7,940 kg /m3 @ 20℃

Melting Range

1357-1385. ℃

Electrical Resistivity

0.989 micro-ohm. m @ 20℃

Specific Heat

460y / kg. ℃@ 20℃

Mean Coefficient of Expansion

14. 4×10 / ℃ @ 20℃

Thermal Conductivity

11. 5W / m. @ 20℃

Curie Temperature

-115℃

Modulus of Elasticity

Tension

196.5 Gpa @ 20℃

Torsion

73.4 Gpa @ 20℃

Poisson’s Ratio

0 . 339 @ 20℃

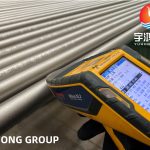

UNS N08800/ALLOY 800 SEAMLESS TUBE CHEMICAL COMPOSITION

Element

Incoloy 800

Incoloy 800H

Incoloy 800HT

Nicke

30.00-35.00

30.00-35.00

30.00-35.00

Chromium

19.00-23.00

19.00-23.00

19.00-23.00

Iron

39.50 min

39.50 min

39.50 min

Carbon

0.10 max

0.10 max

0.10 max

Aluminum

0.15-0.60

0.15-0.60

0.25-0.60

Titanium

0.15-0.60

0.15-0.60

0.25-0.60

Aluminum + Titanium

0.30-1.20

0.30-1.20

0.30-1.20

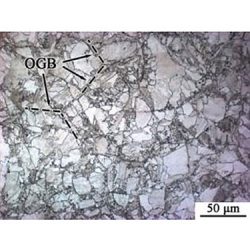

ASTM Grain Size

Not Specified

5 or Coarser

Incoloy 800 Tubes are designed to resist Oxidation and Carburization. The general corrosion resistance is excellent. Incoloy alloy 800 pipe is a widely used material of construction for equipment that must have high strength and oxidation resistance, carburization, and other harmful effects of high-temperature exposure.