LPG Compressor

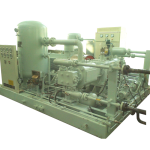

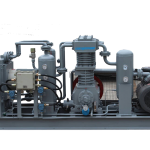

Liquefied petroleum gas (LPG) series oil-free lubricating compressor is one of our domestic products with the characteristics of low speed, high strength components, smooth operations, long service life, convenient maintenance and great LPG compressor prices. Among them, the ZW series compressor is in unit form. It integrates compressor, gas-liquid separator, filter, two-position four-way valve, safety valve, checks valve, explosion-proof motor and chassis. It has the advantages of small volume, lightweight, low noise, good sealing, easy installation and simple operation. LPG compression is mainly used for the unloading, loading, dumping, residual gas recovery and residual liquid recovery of LPG. It is widely used in LPG storage and distribution station, gasification station, gas mixing station, gas filling stations and so on, it is the key equipment in the LPG industry.

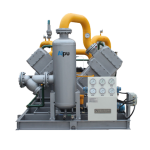

Among our types of gas compressor, LPG gas compressors are one of the best. They are mainly used for the transportation and pressurization of liquefied petroleum gas or gases with similar properties. Therefore, such LPG compressors using LPG compressor oil to operate are the key equipment for liquefied petroleum gas stations, LPG car filling stations, and mixed gas stations, and they are also the ideal equipment to pressurize and recover the gases for chemical companies. Aipu is one of the leading LPG compressor manufacturers, we provide the best LPG gas compressor with reasonable prices.

Types of LPG Compressor

Z-type LPG Compressor

Z-type liquefied petroleum gas (LPG) compressor is a skid-mounted, vertical, single-acting, air-cooled, non-lubricated, reciprocating piston structure unit.It is composed of main engine.

LPG Compressor Working Principle

After the cracking gas below C4 comes out of the separation tower, it enters the inlet of the compressor and pressurizes to 8-12kg in the cylinder of the compressor.

At the same time, it cools and removes heat. When the temperature is lower than the critical temperature (the temperature of gaseous and liquid transformation), most of these gases will liquefy, and only a small amount of carbon can not liquefy. It is called dry gas and will be treated separately.

The liquefied gas is pumped to the pressure storage tank for storage! According to the need can be transported and sub packed, such as car tanker, civil LPG tank and so on.

LPG Gas Compressor FAQs

What are the precautions for LPG compressors?

When the liquid enters the separator of the LPG compressor, it must be stopped immediately;

When the LPG gas compressor starts to run, and it is found that the oil pump has no pressure, it should be stopped immediately;

If the sound of the cylinder and moving parts is abnormal, stop and check immediately;

If each instrument indicates that it exceeds the specified range, stop the gas compressor immediately;

When you smell the burning smell from the machine, you should stop the working of the LPG compressor for inspection;

Check the temperature and vibration of each part of the motor and compressor, and stop if there is any abnormality;

When the safety valve of the LPG compressor fails, it should be shut down for maintenance;

What is liquefied petroleum gas (LPG) ? what’s its application?

Liquefied Petroleum Gas (LPG), one of the petroleum products, is a mixture of propane and butane, usually accompanied by a small amount of propylene and butene.

Main application: Used as a raw material for the petrochemical industry, and it can also be used as fuel.

Liquefied petroleum gas is mainly used as a petrochemical raw material, used for hydrocarbon cracking to produce ethylene or steam reforming to produce synthesis gas, and can be used as industrial, civil, and internal combustion engine fuel. The main quality control indicators are evaporation residue and sulfur content, and sometimes olefin content is also controlled. Liquefied petroleum gas is a flammable substance. When its content in the air reaches a certain concentration range, it will explode when exposed to an open flame.

Where can liquefied petroleum gas (LPG) be applied?

With the development of the petrochemical industry, liquefied petroleum gas, as a basic chemical raw material and a new type of fuel, has attracted more and more attention. In chemical production, ethylene, propylene, butene, butadiene, etc. are obtained from liquefied petroleum gas after separation, which is used to produce synthetic plastics, synthetic rubber, synthetic fibers, and pharmaceuticals, explosives, dyes and other products. Using liquefied petroleum gas as fuel, because of its high calorific value, no smoke, no carbon residue, easy operation and use, has been widely used in people’s lives. In addition, liquefied petroleum gas is also used for cutting metal, baking agricultural products and roasting in industrial kilns.