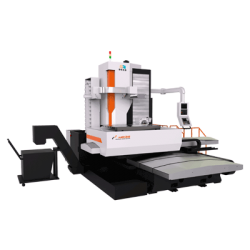

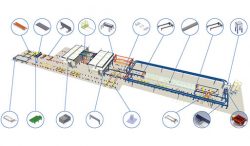

Lubrication Conditions of the Roll Forming Machine

For roll forming machine, it is a product of mechanical equipment, so it needs to be lubricated regularly in the operation process, just like other common types of mechanical equipment. But what we need to pay attention to is that in order to have a good lubrication effect, the following rules must be followed in the lubrication of the roll forming machine:

1. In the process of lubricating the roll forming machine, employees must lubricate the lubrication parts and inspection points specified on the lubrication chart, and do not add or change the oil at will.

2. The lubricating oil used for the roll forming machine must be inspected and it should meet the national standards, and the oil used in all parts and lubrication points must meet the lubrication regulations.

3. When lubricating the roll forming machine, the lubrication parts must be lubricated daily according to the amount of oil and grease specified on the lubrication card. Do a good job in refueling and tank cleaning, quantity control during an oil change or waste oil recovery, and equipment leakage control.

In addition to the above-mentioned aspects, the lubrication of the roll forming machine also needs to meet other more conditions, so as to better ensure the use effect in practical applications.