Notes for Selection of Roll Forming Equipment

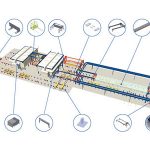

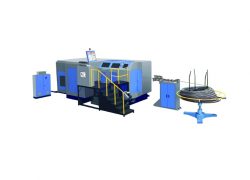

When selecting roll forming equipment, pay attention to the diameters of the three top rolls.

1. It is necessary to match the type of pre-cold-formed steel. The top roller has a small diameter, so the contact surface is small, and it is slightly slippery during processing.

2. When bending non-standard steel, it deforms briefly.

3. Then regarding the diameter and stroke of the hydraulic cylinder of roll forming equipment, the diameter and stroke are based on the output pressure of the hydraulic cylinder and the radius of the processed section steel.

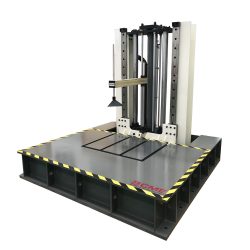

The thickness of the steel plate of the roll forming equipment itself and the quality of the skeleton is also important. The size of the load and the strength of the equipment itself is required. There is also the power of the motor and the quality of the reducer, which must meet the corresponding requirements.

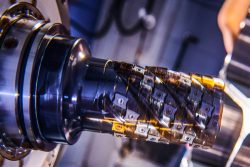

The hydraulic oil with the same trademark used in the system shall be used in the operation of rollforming equipment, and the oil temperature shall be between 45~80℃. Use large flow to remove impurities from the system as much as possible. The hydraulic system should be cleaned more than three times.

After cleaning, clean the filter, replace the filter element and add new oil. Choose the driving method suitable for the oil pump of roll forming equipment among the driving methods of electric, pneumatic, gasoline engine, etc., and understand its capabilities. Based on the influence of the working environment on the working temperature of the oil pump of the roll forming equipment and the cooling conditions of the roll forming machinery, see whether the explosion-proof method can be adopted.