Plastic Injection Molding Service Of Metal Stamping

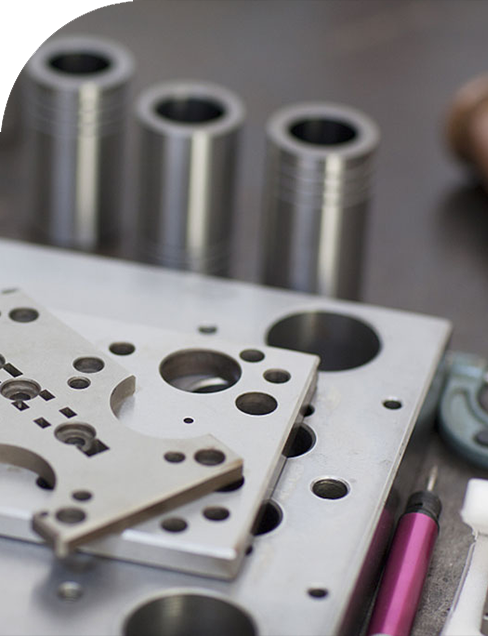

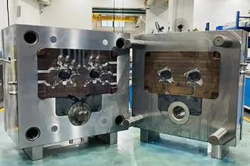

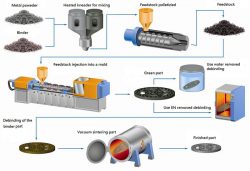

Injection molding refers to the process of heating the plastic, plasticizing and melting, and then injecting it into the cavity of the molding mold. After cooling, the melt solidifies and molds. Orienson has complete supporting resources. In addition to providing hardware stamping parts, Orienson can also provide customers with supporting services such as plastic parts, injection molding of inserts, and hardware assembly, providing customers with one-stop production to facilitate customer control, reduce costs and shorten cycles.

What Is Plastic Injection Molding Process?

01

The Preplastic Process

The pre-plastic process is the plastic material in the barrel into overheating, transportation, compaction, shearing, mixing, homogenization to make the material from glass state to viscous state, so as to meet the requirements of injection molding.

02

Injection Molding Filling Process

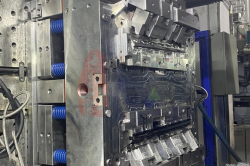

The injection molding filling stage is the screw under the thrust of the injection cylinder, the melt in the storage chamber through the nozzle, mold runner, gate into the cavity.

03

Pressure-retaining And Feeding Process

Continuous injection molding is used to fill the volume vacated by shrinkage of the part.

04

Cooling Finalize Process

After holding pressure, the gate is frozen. The product undergoes a period of cooling and setting.

05

The Process Of Ejecting And Taking Parts

Push the parts out of the injection mold through the push rod of the mold. The product has a certain rigidity and strength after a period of cooling.

Benefits Of Plastic Injection Molding

Injection molding method has the advantage of production speed, high efficiency, automation operation realization, Design and color is various, Shapes can vary from simple to complex and sizes from large to small with precise dimension, injection molding is suitable for mass production with complex shape product and molding processing field.

Features Of Plastic Injection Molding

The injection molding process is easy to be fully automated and realize program control.

One operator can usually manage two or more injection molding machines, so the labor required is relatively low.

It can be shaped with complex shape, clear surface pattern, and high dimensional precision.

High production efficiency, molding can be formed dozens or even hundreds of plastic parts.

Molded plastic parts only need a small amount of dressing, and the waste generated in the molding process can be reused, therefore, the waste of raw materials during injection molding is very little.

The melt has little wear on the mold, so a set of molds can produce large quantities of injection products.