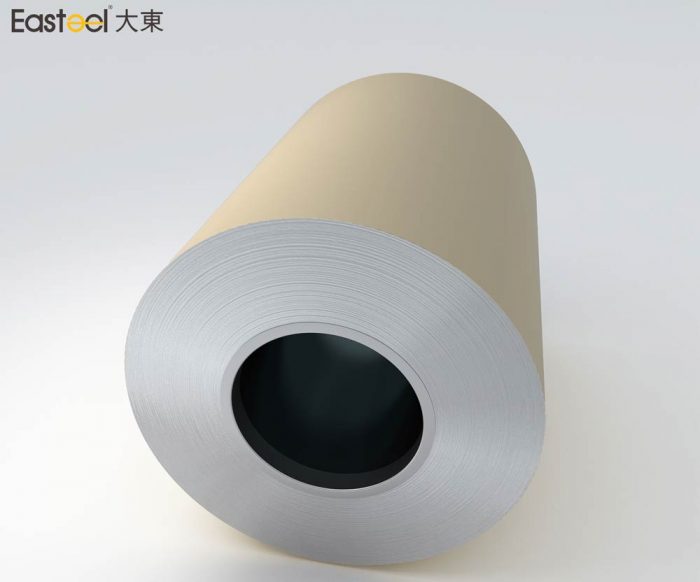

Pre-painted Galvalume Steel (PPGL)

The coating of galvalume steel is composed of 55% aluminium, 43.4% zinc and 1.6% trace elements.

PPGL is a product made of galvalume steel sheet. After surface pre-treatment like chemical degreasing and conversion treatment of galvalume metal, one or several layers of organic coatings are coated on the surface and then cured by baking. Also because there are various colors of organic coatings, color steel coil named after this, referred to as color coated coil or prepainted galvalume steel sheet. The color coated steel coil price of the PPGL sheet is different according to the different patterns of pre-painted coil steel you choose.

Specifications of Pre-painted Galvalume Sheet (PPGL)

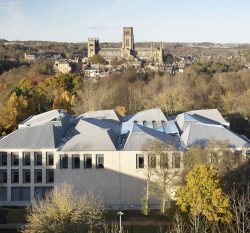

Application of PPGL sheet

According to different thickness specifications and good corrosion resistance, the PPGL is more suitable for severe outdoor environments, which can be used in the power distribution cabinet (thickness of 1.2-2mm), solar water heater (0.32mm), anti-theft door panel, etc.

Differences between PPGI and PPGL

PPGI is short for pre-painted galvanized steel, while PPGL is short for pre-painted galvalume steel. Compared with PPGL, PPGI has relatively active chemical properties, so its anti-corrosion ability is quite different. The test under the same outdoor conditions shows that the service life of PPGL is more than four times that of PPGI. The aluminium-zinc alloy structure of PPGL is composed of 55% aluminium, 43.4% zinc and 1.6% silicon solidified at 600 ℃. The whole structure is composed of aluminium iron silicon zinc to form a dense quaternary crystal, so as to form a strong barrier to effectively prevent the penetration of corrosion factors.

1. Corrosion resistance:

Aluminized zinc has a stronger protective effect and better corrosion resistance than galvanized products. The corrosion resistance of the “55% aluminium-zinc plated steel coil” comes from the barrier protection function of aluminium and the sacrificial protection function of zinc. When zinc makes sacrificial protection in the cutting, scratch and coating scratch parts, aluminium forms an insoluble oxide layer to play the function of barrier protection.

2. Heat resistance:

The heat resistance of 55% Al Zn alloy steel plate is better than that of galvanized steel plate, which is similar to that of PPGI. PPGL steel plate can be used in high-temperature environments up to 315 ℃.

3. Reflectivity:

55% Al Zn alloy plated steel plate has high reflectivity, making it a heat resistant barrier; The thermal reflectivity of PPGL is almost twice that of PPGI. Therefore, it can also achieve an energy-saving effect by acting as a roof and panel without painting.

4. Paintability:

Due to the excellent adhesion between the zinc layer of PPGL and the paint, when used as a signboard for general purposes, it can be painted without pretreatment and weathering treatment; PPGI needs weathering treatment and pretreatment. So that the surface of the PPGL sheet is smoother than that of the PPGI sheet.