Precautions of Cold Roll Forming Machine Operation

Precautions of Cold Roll Forming Machine Operation

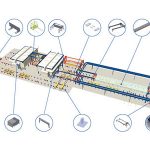

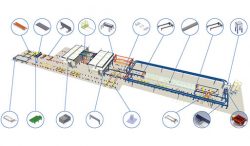

As cold-formed steel processing equipment, the cold roll forming machine should be operated with more attention. Cold roll forming machines are very popular because of their high working efficiency and low noise. Because cold roll forming machines are widely used, it is necessary to pay attention to the operation of cold roll forming machines. Therefore, today we will introduce you to how to operate cold roll forming machines safely.

1. The cold roll forming machine should first adjust the pressing speed according to the properties of the material to be processed and the processing curvature, which can prevent the workpiece from breaking and splashing during processing and causing personal injury.

2. When the cold roll forming machine is operated by multiple people, the foreman must direct the processing parts when they advance and retreat, so that multiple people can cooperate closely and move in the same way to prevent hidden dangers caused by insufficient cooperation.

3. The height of the notch of the cold roll forming machine should be selected to be equivalent to about 8 times the width of the plate thickness, so as to ensure that the workpiece can enter smoothly.

The production efficiency of the cold roll forming machine is very high, but more attention should be paid to the operation of the staff in the production, so as to ensure the continuous improvement of production efficiency.

Zhejiang Jinggong Science Technology Co., Ltd. has international advanced core technology and more than 50 years of experience in special equipment manufacturing, cooperating with universities and colleges. If you have any needs, please feel free to consult us.