Precision Metal Stamping Parts

Precision Metal Stamping PartsBasic Info.Trade Term: EXW,FOB,CIF.CFRPayment Term: T/T,L/C, Western UnionDelivery Time:7-30daysPlace of Origin: Ningbo, China

Information About HEWCHO Precision Metal Stamping Parts

Features of precision metal stamping parts:

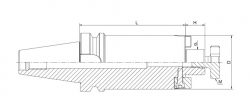

·Product name: Precision Metal Stamping Parts·Material:Carbon Steel, Barss, Copper, Stainless Steel, Alumnum, Titanium Alloy·Machining Tolerances:0.1mm·Machining Process:Punching, edging, pressing and welding·Min. Order:1000PCS·Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, Anodization, Chemical Fim,·Packing: Carton Box, Blister tray, Pallet, Wooden Case.·Certificate:ISO9001:2008, ISO/TS16949The precision metal stamping in China is of good quality. The china precision stamping is one of the most popular products in our company.

What we can Provide:

Machining Material:

CNC Machining Service

Carbon Steel

CNC Turning Service

Stainless Steel

CNC Milling Service

Aluminum

Cold Forging Service

Brass

Metal Stamping Service

Copper

Titanium Alloy

Surface Treatment

Application:

Heat Treatment

Automobile Spare Parts

Sand Blasting

Electrical Appliance Industry

Polishing

Electronics Industry

Zinc Plated

General Industry

Anodization

Machinery and Equipment

Chemical Fim

Hydraulic and Pneumatic

Description of precision metal parts

Stamped parts are products made of plate-shaped materials with arbitrary shapes and contours. Especially in the field of sheet metal processing , the production of precision metal components is an integral part of the manufacturing process, since sheet metal parts often have to be manufactured with a high number of recurring shaped elements such as recesses. Thereby making fast processing times and consistently high quality, even in large numbers, punching an indispensable basic technology. Typical examples are brackets, clamps, washers, seals or fasteners, which are manufactured by means of stamping.

The benefits of Stamping

●Diverse contours and transformations

●No thermal material interference

●An economical and flexible production

●Consistent quality even with large quantities

Applications for stamped parts

●Fittings and angles

●Components for heat exchangers

●Carrier elements and holders

●Printed circuit boards and electrical contacts

What stamping parts can be manufactured?

According to your requirements and cost-optimized, our suppliers manufacture high-quality edgebands in a wide variety of shapes. Whether for dressing, stiffening or covering – Here you will find optimal manufacturing solutions for every imaginable application. Steel, aluminum, stainless steel, copper and zinc sheets with different surfaces are immediately available, which is why your end product is delivered on time.