Purpose and Required Materials of Brass Forging Process

Purpose and Required Materials of Brass Forging Process

1. Introduction of Brass Forging Process

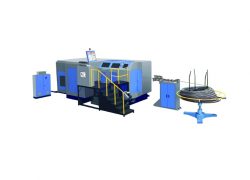

Brass forging process is a process of applying pressure to brass blank by forging machine to produce plastic deformation so as to obtain forging products with certain mechanical properties, shapes and sizes. Forging is one of the two components of forging and stamping. Forging can eliminate the defects of as-cast porosity in brass smelting process. It can optimize the microstructure. At the same time, since the streamline brass is completely preserved, the mechanical properties of forged metal products are generally better than those of castings made of the same material.

2. Materials for Brass Forging Process

The materials required for the brass forging process are bar stock, ingot, brass powder and liquid brass. The ratio of the cross-sectional area of brass before deformation to the ratio after deformation is called the forging ratio. The correct selection of forging ratio, reasonable heating temperature and holding time, reasonable initial and final forging temperatures, and reasonable deformation degree and deformation speed have much to do with the improvement of the quality of forged products (namely brass) and the reduction of cost.

Generally, small and medium-sized forged brass is made of round or square bars. Batch production requires brass bars to have uniform & good grain structure and mechanical properties, accurate shape and size, as well as high-quality surface. Reasonable controlling of the heating temperature and deformation conditions helps produce forged brass with excellent performance.

3. The Purpose of the Brass Forging Process

(1) Refining the coarse casting structure and strengthening the tightness of micro void in the brass blank to improve the mechanical property and service life;

(2) Forging the brass blank into streamline metal products with various shapes.