Quality and Innovation in China Rubber Oil Seal Manufacturing

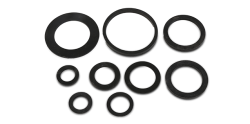

In the realm of industrial essentials, China rubber oil seal stands tall as a symbol of reliability and innovation. These seals, crucial components in machinery and automotive sectors, exemplify the pinnacle of Chinese engineering prowess.

China rubber oil seals are renowned for their durability and precision. Manufactured using advanced synthetic rubber compounds, they excel in maintaining tight seals even under extreme conditions of temperature and pressure. From automotive engines to industrial machinery, these seals ensure optimal performance and longevity, reducing maintenance costs and downtime.

The production of China rubber oil seals is a testament to continuous innovation. State-of-the-art manufacturing facilities employ cutting-edge technologies such as computer-aided design (CAD) and automated production lines. This ensures consistent quality and adherence to international standards, meeting the stringent requirements of global markets.

Moreover, China rubber oil seals are not just about functionality but also environmental responsibility. Manufacturers prioritize eco-friendly practices, employing recyclable materials and minimizing waste during production. This commitment to sustainability aligns with global efforts towards greener manufacturing practices.

In recent years, China rubber oil seals have gained prominence worldwide, establishing a reputation for excellence and reliability. Exported to markets across Asia, Europe, and the Americas, these seals have become integral to diverse industries, powering the engines of global trade and commerce.

In conclusion, China rubber oil seals embody the fusion of tradition and innovation in manufacturing. With a commitment to quality, precision, and sustainability, they continue to set benchmarks in the global marketplace. For industries seeking reliability and performance, China rubber oil seals remain the seal of choice, symbolizing China’s leadership in engineering excellence.