Rotary Table For Welding

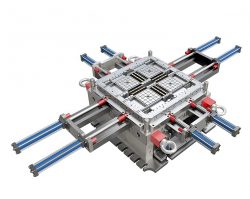

The rotary welding table consists of a welding table, a positioner and a robot. As a 3D welding table, it offers excellent clamping possibilities. rotary welding table is designed for a total 360° rotation of the table surface. The rotary table is available in two variants – 1) motorized, and 2) manual.

The rotary fixture table has 1 precision machined surface. A well-designed and well-balanced rotary table are able to move important heavy objects at an impressive speed.

Whether it’s a hydrostatic linear axis or a rotary axis or a combination of the two – we can provide a total solution. With hydrostatic guides, surface wear can be avoided, for example, under extremely high loads, making the table suitable for demanding and high-precision machining. Optimum damping properties enable longer tool life and high-precision workpiece machining. For the service life and accuracy of the rotary table, it is not only the possible load that is most critical, but also the largest possible bearing diameter that matches the table size. The structure of the machine base itself is very compact and space-saving. It is well protected with a steel cover. All required adjustment and control elements are located in the power box integrated in the turntable for easy operation. Thanks to standardized plug-in interfaces, the rotary table can be easily connected to all machine tools.