The Role and Significance of Plastic Chair Mould Factories in Modern Furniture Production

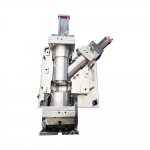

Plastic chair mould factories are an integral part of the furniture industry, playing a crucial role in the mass production of affordable and versatile seating solutions. These factories specialize in the creation of moulds that are used to produce plastic chairs through a process known as injection moulding. The significance of plastic chair mould factories extends beyond the production line, impacting design innovation, material efficiency, and environmental sustainability. One of the primary advantages of plastic chair mould factories is their ability to produce chairs in large quantities at a relatively low cost. This is due to the efficiency of the moulding process, which allows for the rapid creation of identical chair parts. The use of plastic as a material also contributes to the affordability, as it is less expensive than traditional materials like wood or metal. In addition to cost savings, plastic chair mould factories also contribute to design flexibility. Moulds can be designed to create a wide variety of chair shapes and styles, allowing manufacturers to respond quickly to changing market trends and consumer preferences. This adaptability is a key factor in the competitive furniture market, where innovation and variety are highly valued. Environmental considerations are also important for plastic chair mould factories. Many are now focusing on the use of recycled plastics and biodegradable materials to reduce the environmental impact of their products. By doing so, these factories are not only meeting the demands of eco-conscious consumers but also contributing to a more sustainable future. The process within a plastic chair mould factory typically involves several stages. First, designers create a prototype of the desired chair, which is then used to develop a mould. This mould is made from a durable material, such as steel, and is designed to withstand the high pressures and temperatures involved in the injection moulding process. Once the mould is ready, molten plastic is injected into it, taking the shape of the chair components. After cooling and solidification, the individual parts are assembled to form the final product. In conclusion, plastic chair mould factories are essential to the furniture industry, offering a combination of cost-effectiveness, design flexibility, and environmental responsibility. As the demand for affordable and sustainable seating options continues to grow, the role of these factories is likely to become even more significant in the future.