The Role of PVC Calcium Carbonate in Enhancing PVC Performance

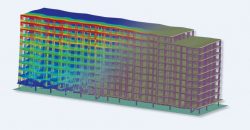

In today’s ever-evolving world, the demand for durable and versatile materials is increasing. Among these materials, polyvinyl chloride (PVC) has emerged as a popular choice due to its excellent qualities such as chemical resistance, low cost, and easy processability. However, improving its mechanical properties without compromising its affordability has always been a challenge. PVC calcium carbonate, an additive extensively used in the PVC industry, is a promising solution that enhances PVC performance in multiple ways. Enhancing Mechanical Properties: One of the primary benefits of adding calcium carbonate to PVC is its ability to enhance its mechanical properties. By incorporating the mineral filler into the polymer matrix, a synergistic effect occurs, leading to improved tensile strength, flexural modulus, and impact resistance. This ensures that PVC-based products can withstand greater stress, making them suitable for a wide range of applications, including construction, automotive, and packaging industries. Reducing Material Costs: Another advantage of using PVC calcium carbonate is its cost-effectiveness. Compared to other mineral fillers, such as talc or kaolin, calcium carbonate is more affordable and widely available. By incorporating this filler into PVC formulations, manufacturers can reduce material costs while maintaining the desired performance characteristics. This is particularly beneficial for industries that require large volumes of PVC, such as pipe manufacturing. Improving Processing Characteristics: In addition to enhancing mechanical properties and reducing costs, calcium carbonate also improves the processing characteristics of PVC. The mineral filler acts as a lubricant, reducing friction and improving flow. This results in easier processing during extrusion or injection molding, leading to higher productivity, energy savings, and reduced wear and tear on processing equipment. Environmental Considerations: Apart from its technical benefits, PVC calcium carbonate also offers environmental advantages. Due to its natural abundance and low toxicity, this mineral filler is considered eco-friendly. Additionally, its incorporation into PVC reduces the dependence on petroleum-based plasticizers, further supporting sustainable manufacturing practices. Conclusion: PVC calcium carbonate is a crucial additive in the PVC industry that offers numerous benefits. Its ability to enhance mechanical properties, reduce material costs, improve processing characteristics, and support environmental sustainability makes it an indispensable tool for manufacturers. Embracing the use of PVC calcium carbonate paves the way for the development of innovative and sustainable PVC-based products that meet the ever-growing demands of various industries.