THE SPECIFIC FUNCTION AND WORKING PRINCIPLE OF SEWAGE TREATMENT CENTRIFUGE

With the development of economy, people pay more and more attention to environmental protection, and the importance of sewage treatment to life and enterprises is becoming more and more obvious. It is not uncommon for many enterprises to shut down for rectification due to unqualified sewage discharge. Therefore, this paper mainly introduces the specific function and working principle of the sewage treatment centrifuge.

Sewage treatment refers to the use of professional sewage treatment equipment to treat domestic and industrial wastewater to reduce or completely eliminate pollutants contained in sewage, through physical methods, chemical reactions or biological treatment processes, such as reducing nitrogen and phosphorus in sewage. content. Nitrogen and phosphorus are the main chemicals responsible for eutrophication of water bodies.

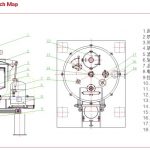

The horizontal centrifuge machine in sewage treatment is one of the equipment with better effect on sewage treatment. In the sewage treatment industry, the residual water content after slurry concentration and digestion is 94% to 96%, and the volume is still large. For further comprehensive utilization and disposal, dehydration treatment should be carried out to increase the content of mud cake. The sewage treatment equipment commonly used in large and medium-sized sewage treatment plants mainly includes vacuum filter press, belt filter press, decanter centrifuge, etc. The sludge centrifuge used for sewage treatment has sustainable production, convenient operation and high degree of automation.

1. The sewage centrifuge mainly treats the organic matter in the sewage

The insoluble substances contained in the sewage are intercepted by the power grid and sent to the sludge tank, and the residue after aeration by the gas suspension equipment is also sent to the sludge tank. There are few pollutants in the sludge tank, but it also contains harmful substances. Solid-liquid separation needs to be carried out by sludge dewatering. After disinfection, the sewage is evenly discharged, and the sludge can be transported regularly or the drum and screw of the sewage treatment centrifuge can rotate at a high speed in the same direction with a certain speed difference. The material is continuously introduced into the inner cylinder of the conveying screw through the feeding pipe, and enters the drum after being accelerated. Under the action of the centrifugal force field, the heavy solid material is deposited on the drum wall to form a sediment layer. The conveying screw continuously pushes the deposited solid material to the tapered end of the drum and discharges it out of the machine through the slag discharge port. The lighter liquid phase forms an inner liquid ring, which continuously overflows the barrel through the overflow port at the large end of the barrel and discharges the machine through the drain port.

2. The specific function of the sewage centrifuge is to achieve solid-liquid separation

A sewage centrifuge is a commonly used equipment. Due to the different rotation speeds, the position of the centrifuge in the equipment is also different due to the quality of sewage and sludge, so as to achieve the purpose of solid-liquid separation.