What is a “non-sparking” tool?

What is a “non-sparking” tool?

“Non-sparking”, “spark reduced”, “spark-resistant” or “spark-proof” tools are names given to tools made of metals such as brass, bronze, Monel metal (copper-nickel alloy), copper-aluminum alloys (aluminum bronze), or copper-beryllium alloys (beryllium bronze).

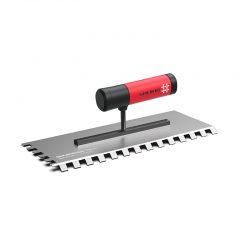

Commonly used hand tools are often manufactured of steel alloys. Preferred “non-sparking” metals have less tensile strength than steels usually used to make tools. A lower tensile strength means the metal has less strength or resistance to tearing apart when stretched under test conditions. It also means that these tools are softer, wear down more quickly than ordinary steel tools, and have to be dressed more frequently.

What are the hazards of both “sparking” and “non-sparking” tools?

Both “sparking” and “non-sparking” materials can cause ignition. Two types of hazards are associated with tools manufactured of either material:

Ignition by friction, with impact on each other or on other materials such as steel or concrete, in which an “ordinary” (mechanical or frictional) spark is generated. All tools can ignite flammable mixtures by sparks generated by friction or impact. However, this is true only when the generated spark is incendive: that means a spark that has to have enough heat content (i.e., enough mass and sufficiently high temperature) and has to last long enough to heat a flammable air-vapour mixture above its ignition temperature. This is more likely in the case of sparks formed when using a metal grinder that a spark generated when a hammer strikes some metal.

Ignition by a chemically-generated spark, caused by impact between certain metals and some oxygen-containing substances (such as rust, which is iron oxide).

If you want to get more information about the non-sparking tools, welcome to contact us today or request a quote.

![AIDA64 Extreme/Engineer 7.00.6700 Cracked + License Key [Updated]](https://socialsocial.social/btabcloud/uploads/2024/01/download-jpeg-17062552564p8lc-250x250.jpg)