WHAT TOLERANCES WOULD YOU WANT WHEN MANUFACTURING THE PARTS AND PRODUCTS

When you offer us the 2D and 3D drawings for quotes on new projects, you must specify the dimensions of the key areas on the part and the required industry standard sheet metal fabrication tolerances. In most cases, very strict tolerances are neither practical nor desirable, so let’s focus on the tolerances that we specified for most projects at LC Rapid, why our rapid prototyping factory do this, and what it means for your parts and products.

What are sheet metal fabrication tolerances?

Tolerances are acceptable deviations away from precise measurements or dimensions. It’s often expressed as a value of “+/-“. If the dimensions on a given feature are 50 mm, the tolerance will be at a number slightly higher or slightly below a certain number. 50.1mm – 49.9mm represents a tolerance of 0.1mm of +/- but sometimes the tolerance is expressed as a +0/-.2. In this way, the specification states that a given feature cannot be bigger than the nominal value, but can be slightly smaller.

Since there will be many possible movements and must be explained, we should find a compromise within the shortest time frame, tolerance, and minimum costs. Perfection is impossible, so we need a standard to make parts and products.

What is ISO 2768-1 standard tolerances for sheet metal fabrication?

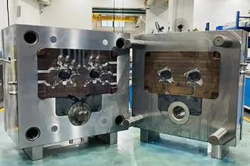

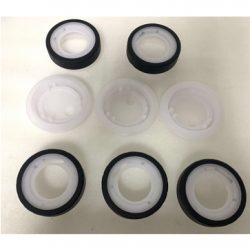

This is the industry standard for covering linear, flatness, radius, determining tolerances, and angular dimensions, and more. At LC Rapid, we validate our sheet metal fabrication services for tolerance classification of ISO 2768-1 fine (metal) and media (plastic). The most recent tolerance in this classification system drops to 50 microns or .002 inches. It’s very small.

That’s what most of the projects we’re referring to expect, and that’s enough for most applications. The standard is agreed by manufacturers around the world to produce lots of parts and products every day for our customers. It’s reliable and repeatable on modern CNC machines, using high-grade materials and cutting tools, making it the bottom line for high-quality manufacturing of mass-produced products.

How will the industry standard sheet metal fabrication tolerances affect your parts and products?

What do the numbers mean for the way your section looks, feels and executes? ISO 2768-1 fine allows all features, holes, mating faces and grooves to be in the right position. The screw will smoothly enter its mating thread, no free play (too loose) or no binding (too tight). The cover will close flat with a nice uniform seam around. Parallel will will be parallel, vertical will be vertical, all degrees exceeding most normal expectations in the real world. To be honest, in most cases, you don’t want to be more tolerant than this.

Why are the strict sheet metal fabrication tolerance standard not always a good thing?

All materials expand and contract with temperature. They can be deformed under load, moved by vibration, or worn over time. So, even if a feature or size is “perfect” manufactured in the factory, it’s not perfect once it is put into use. This is a reality for all objects that need some free play to combine and pull apart.

In addition, from the manufacturer’s point, the pursuit of perfection in any function – such as the position of the screw hole -it means that you will lose it. In production, the small, incremental improvement of tolerances is hard to achieve in some ways. They require longer processing times specialized equipment, higher costs and climate-controlled clean rooms. Such investments may be necessary for luxury, aerospace components and watches sophisticated scientific instruments but they are rarely or desirable for rapid prototyping or low volume manufacturing.

What standard sheet metal fabrication tolerance is best for your project?

It depends on what your part and product are for and how it’s used. We can confidently say that the tolerance better than a 2768-1 fine is rarely necessary and you will improve economic efficiency and still get a big portion if you use the above recommendations as a guide. When you’re ready to learn more about engineers submitting offers, our engineers are on hand to help you with the technical information.