Dimethylcyclosiloxane (DMC)

Product Name: Dimethylcyclosiloxane (DMC)

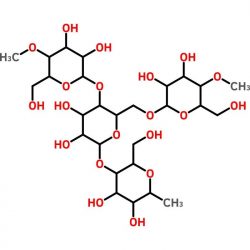

Molecular Formula: [(CH3 ) 2 SiO]n ,n=3~7

CAS No.: 69430-24-6

Physical and Chemical Properties:

Flash Point: 55℃

Relative Density (water=1): 0.956

Appearance: Colorless transparent liquid without visible impurity

Technical Data of Dimethylcyclosiloxane

Item

Index

Chroma/ Platinum-cobalt scale/ Hazen unit

≤10

Refractive index nD20

1.3960~1.3970

Content of Dimethylsiloxane cyclists mixture/%

≥99.80

Content of Hexamethyldisiloxane/%

≤0.005

Properties and Uses of Dimethylcyclosiloxane

Dimethylcyclosiloxane is colorless, inflammable, and can not dissolve in water, but can dissolve in organic solvents such as benzene, etc. It can be used to synthesize organic silicon polymer by acid or alkali catalysis to manufacture silicone oil, silicone rubber, etc.

Package, Storage, and Handling of Dimethylcyclosiloxane

Steel drum, net weight 190kg/drum or International Bulk Container, net weight 950kg/IBC or ISO TANK. Store in a cool, dry, well-ventilated area and keep away from oxidant, acid, and alkali.

The storage area should be equipped with the corresponding species and quantity of fire equipment and leakage emergency equipment. Handling according to hazardous substances. Be careful when loading and unloading to avoid damages to the package.

Chemical Stability: Stable in closed containers under specified storage and handling conditions.

Conditions to Avoid: Incompatible materials, any sources of ignition or heat, exposure to moist air or water. Incompatibilities with Other

Materials: Strong oxidizing agents, acids, bases. Hazardous

Decomposition Products: In the case of a fire, oxides of carbon, hydrocarbons, silicon oxide, fumes, and smoke may be generated by thermal decomposition or combustion.

Hazardous Polymerization: May occur

Application of Dimethyl cyclosiloxanes

Primary forms of dimethyl cyclosiloxanes are mainly used for ring-opening polymerization to form silicone oils, silicone rubbers, and silicone resins of different polymerization degrees. These polymers are further processed into products for a wide range of applications in construction, electronics, textiles, automotive, personal care, food, machining, and to a lesser extent, direct applications.

Silicone resin derivatives, used as stabilizers, suspending agents, or thickening agents.

Silicone: A substance made from silica (sand is a type of silica). Since silicone has liquid properties, which is easy to smear on the skin, and has a silky touch when applied to the skin, has moisturizing properties, and actually has a water retention function when the skin is wet. There are also silicone resins that promote wound healing and improve the appearance of skin scars.