Exploring Post And Beam Construction And SIPs In A-Frame Timber House Plans

In the realm of sustainable architecture and environmentally-conscious living, the utilization of innovative construction techniques has gained significant traction. Among these methods, Post and Beam Construction coupled with Structural Insulated Panels (SIPs) has emerged as a promising approach, particularly in the creation of A-frame timber house plans. Let’s explore the intricacies of these techniques and understand how they contribute to sustainable, energy-efficient, and aesthetically pleasing homes.

Post and Beam Construction: A Foundation of Strength and Beauty

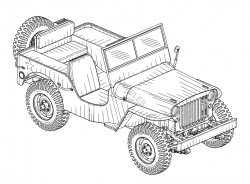

Post and beam construction is an ancient building method that continues to be revered for its durability, flexibility, and timeless appeal. This method relies on vertical posts and horizontal beams, allowing for open, spacious interiors with a striking visual aesthetic. The structural integrity of post and beam homes enables the incorporation of large windows, maximizing natural light and offering picturesque views of the surrounding environment.

One of the significant advantages of post and beam construction lies in its adaptability. Homeowners have the freedom to customize the design and layout according to their preferences, whether it’s creating open-plan living spaces or incorporating unique architectural elements.

A-Frame Timber House Plans: Fusion of Elegance and Practicality

A Frame Timber House Plans have garnered attention for their distinctive triangular shape, reminiscent of traditional cabins but now adapted into modern, sustainable homes. These houses often utilize timber frames, embracing the natural beauty and strength of wood. The A-frame design not only adds an appealing visual aspect but also facilitates efficient rainwater runoff and snow shedding.

The beauty of A-frame timber houses lies in their versatility. From cozy cabins nestled in serene landscapes to spacious family homes, the adaptability of this design makes it an attractive choice for those seeking both aesthetic charm and functional living spaces.

SIPs Construction: Revolutionizing Energy-Efficient Homes

SIPs Construction on the other hand also revolutionized the construction industry by offering superior insulation, structural strength, and rapid installation. These panels consist of an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB). The result is a highly energy-efficient building envelope that significantly reduces heating and cooling costs while ensuring airtightness and thermal comfort.

When combining post and beam construction with SIPs, homeowners benefit from the structural integrity of the frame coupled with the exceptional insulation properties of SIPs. This synergy creates homes that are not only visually appealing but also energy-efficient and environmentally friendly.

Building the Future: Harmonizing Tradition with Innovation

The amalgamation of post and beam construction, A-frame timber house plans, SIPs, and Building With Sips technology represents a harmonious blend of traditional craftsmanship and modern innovation. This approach allows for the creation of sustainable dwellings that prioritize energy efficiency, durability, and aesthetic allure.

As we navigate towards a more sustainable future, embracing these construction techniques can pave the way for eco-friendly housing solutions. From reducing carbon footprints to providing comfortable living spaces, the combination of these methods holds the promise of sustainable and fulfilling lifestyles.

Conclusion

The combination of Post and Beam Construction techniques with A-frame timber house plans, fortified by SIPs technology, exemplifies a harmonious union of tradition, innovation, and sustainability. Adopting these methodologies and construction techniques with the help of Trinity Buildings Systems not only results in captivating architectural designs but also fosters a greener and more energy-efficient way of living.