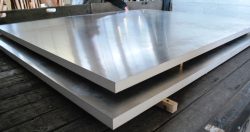

Galvanized Steel Sheet

Description of Galvanized Rolled Steel

Hot dipped galvanized steel sheet is a carbon steel sheet coated with zinc on both sides through a continuous hot-dip process. When the heated steel strip is in contact with the molten zinc, the coating is firmly adhered to the steel by the iron-zinc alloy adhesive layer formed by the diffusion process. One of the disadvantages of galvanizing is that if the zinc coating is scraped off the steel, the steel will lose its protection and may fail.

Specification of Galvanized Steel Sheets

Product name

Galvanized Steel Sheets

Zinc Coating

20-120g/m2

Thickness

0.14-1.0mm

Width

600-1250 mm

Length

custom

Thickness Tolerance

+0/-0.001

Width Tolerance

+/-0.06

Length Tolerance

+/-0.06

Surface Structure

Mini/Big Spangle

Surface Treatment

Anti-Finger printing, Chromated, oiled/ non-oiled

Finish

Galvanized

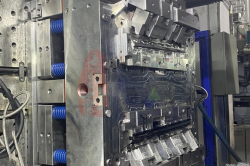

Galvanized Steel Sheet Production Process:

1. Uncoiler

2. Welder

3. Entry Looper

4. Pre-treatment

5. Annealing Furnace

6. Zinc Pot

7. Cooling Tower

8. Water Quench Tank

9. Skin Pass

10. Tension Leveler

11. Passivation Coater

12. Exit Looper

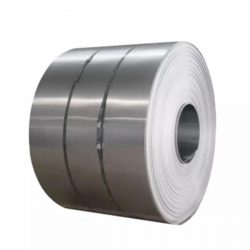

13. Recoiler

Quality Control of Galvanized Steel Sheet

Use bending machine, pencil hardness tester, gloss meter, meteorological tools, row lattice unit, micrometer tools, thickness gauge to control the quality of galvanized steel coil.