Gas Diesel Thermal Oil Boiler

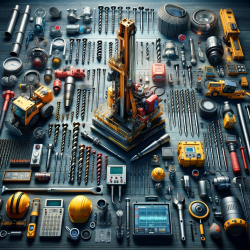

Gas-fired heat-conducting oil furnace is a new type of special boiler, which has the characteristics of low pressure and high temperature. Its heating temperature can reach 340℃ in liquid phase or 400℃ in vapor phase. Those who need uniform and stable heating, and do not allow direct flame heating process heating temperature between 150℃-380℃ in various occasions can use organic heat carrier heating. Heat conduction oil heater using digital display temperature controller temperature control, with over temperature alarm, low oil level alarm, over pressure alarm function, it is chemical, petroleum, machinery, printing and dyeing, food, shipbuilding, textile, film and other industries in an efficient energy saving heating equipment.Brief introduction of structure:

Gas-fired heat-conducting oil furnace is a new type of special boiler, which has the characteristics of low pressure and high temperature. Its heating temperature can reach 340℃ in liquid phase or 400℃ in vapor phase. every Is the need for uniform and stable heating, and does not allow direct flame heating process heating temperature between 150℃-380℃ in various occasions can use organic heat Carrier heating.

Oil (gas) organic heat carrier furnace takes oil (gas) as fuel and heat conduction oil as medium, and uses hot oil circulating oil pump to force liquid phase circulation of medium to transport heat energy

After the heating equipment is used, it is returned to the heating furnace for reheating. It has high working temperature under low pressure, and can control the operation of medium accurately.

The system has a high heat utilization rate and convenient operation and maintenance due to the integral installation of modules. It is a kind of high energy and energy saving heating equipment. Fuel oil (gas) by burning

After the ignition of the burner, the high temperature flame enters the inner coil tube to form a radiant heating surface, which is formed by rotating 180° forward through the back of the inner coil into the sandwich area of the inner and outer tubes

Convection heating surface. Then in the upper part of the sandwich into the middle and outer coil of the second layer of the sandwich area, at the back of the second layer of the sandwich area to the chimney into the atmosphere.