High Temperature-resistance TPO

The modification of ATP for polyolefin elastomers mainly reflects the following technical characteristics:

1. Improved Low-temperature Resistance:

In the application of cable insulant, the modification TPO of ATP can not only meet the requirement of electric performance from the insulant but also display a more broad temperature resistant character——displaying excellent mechanical properties and aging properties at the test temperature of -50℃—+125℃. So, this is the optimized insulant for wires and cables which have special requirements for low-temperature resistance.

2. Improved shrinkage resistance:

The jacket made up of TPO wire and cable insulant from ATP keeps its section surface smooth and orderly with little retraction rate after immersing in solder machine (350℃/2″). In the application of high-temperature-resistant cables (temperature≤125℃) such as charging vehicle cables (EV Cable), equipment connection cables, etc., the jacket made up of TPO wire and cable insulant from ATP takes the place of XLPE materials to meet the requirements of insulant high-temperature aging and shrinkage for nominal cables. And this can simplify the processing procedures by a large margin and improve the processing efficiency and yield.

Application: TPO has the characteristics of small specific gravity, good impact strength, and low-temperature brittleness, and is suitable for applications in the cable industry.

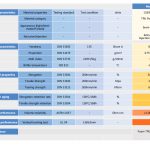

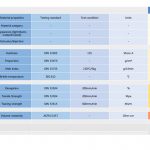

Technical Data of High Temperature-resistance TPO

Technical Data Sheet

Model

Material Properties

Test Standard

Test Condition

Unit

2895F-ESS-1008S

General Characteristics

Material Category

–

–

–

Appearance(Light/Semi-matte/Frosted)

–

–

–

Extrusion/Injection

–

–

–

Physical Characteristics

Hardness

ISO 48

15S

Shore A

97

Proportion

ISO 1183

–

g/cm³

0.93

Melt Index

ISO 1133-1:2011

190℃/2.16kg

g/10min

1.7

Brittle Temperature

ISO 812

–

℃

Mechanical Properties

Elongation

ISO37:2017

200mm/min

%

590

Tensile Strength

ISO37:2017

200mm/min

Mpa

33.367

Tearing Strength

ISO34-1:2015

500mm/min

KN/m

Hot Air Aging

Elongation Retention Rate

ISO37:2017

–

%

Tensile Strength Retention Rate

ISO37:2017

–

%

Electrical Performance

Volume Resistivity

ASTM D257

–

Ohm-cm

permittivity

ASTM D150

–

–

Combustion Performance

Vertical Burning Test

UL 94

3.0/6.0mm

–

Oxygen Index

ASTM D2863

–

%

Feature