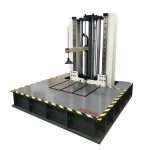

KRD50 Transportation Simulation Vibration Testing Machine

KRD50 transportation simulation vibration testing machine can replace the actual running automotive test to complete the road transportation simulation test of packaged or unpackaged products in the laboratory. The simulation conditions are as follows: the random vibration environment generated when the vehicle speed is 20~80km/h on the intermediate surface of 3nd or 4th highway. It is applied to evaluate the adaptability of the product to withstand the vibration of automobile transportation under packaged or non-packaged condition and to evaluate its structural integrity.

FEATURES OF KRD50 TRANSPORTATION SIMULATION VIBRATION TESTING MACHINE

Adopt a mechanical random vibration simulator, and adjust the system’s natural frequency, excitation frequency, and vibration amplitude to make the test table meet the technical index requirements

Simple and reliable structure, the operation is convenient. It is especially suitable for transportation tests on large-scale and large-mass products

Adopt combined spring suspension, which can achieve a vibration isolation effect without a special foundation

Vehicle transportation vibration is broadband random vibration, and the instantaneous value of vibration basically meets the normal distribution

The simulation of broadband random vibration is used a subband approach, each subband contains a main natural frequency and meets the power spectrum of the subband

Adopt truck chassis suspension technology, the acceleration factor can be adjusted

TABLE OF KRD50 TRANSPORTATION SIMULATION VIBRATION TESTING MACHINE

A transportation simulation vibration test machine is a mechanical random vibration simulator, which is laboratory equipment that can reproduce transportation vibration.

The transportation simulation vibration test table mainly includes a bottom plate, hanging spring, hanging spring bracket, work table, leaf spring, wheel, reducer transmission mechanism, supporting block, etc.

1. bottom plate; 2. hanging spring; 3. hanging spring bracket; 4. work table; 5. leaf spring; 6. drum wheel; 7. rubber wheel; 8. reducer transmission mechanism; 9. supporting block; 10. Body rack.