Limitations Of Internal Gear Pumps

Internal Gear Pumps are self-priming and can dry up, although if the gears are wet, they will also improve their oil absorption characteristics. The gear needs to be lubricated by the pumped liquid and should not be idling for a long time. Some gear pump designs can run in either direction, so, for example, the same pump can be used to load and unload containers.

Tight tolerances between gears and housings mean that these types of pumps are prone to wear, especially when used with abrasive fluids or feeds that contain entrained solids. The external gear pump has four bearings in the pumped medium, and the tolerances are strict, so it is not as suitable as the internal gear design to handle abrasive fluids. For these applications, internal gear pumps are more robust, with only one bearing (sometimes two) running in the fluid. Gear pumps should always be equipped with a filter screen on the suction side to prevent it from accumulating large amounts of potentially damaged solids.

Generally, if you want the pump to be able to handle abrasive solids, it is recommended to choose a pump with a larger capacity so that it can run at a lower speed to reduce wear. However, it should be remembered that the volumetric efficiency of the gear pump will decrease at lower speeds and flows. The operating speed of the gear pump should not exceed the recommended speed.

For high temperature applications, it is important to ensure that the operating temperature range is compatible with the pump specifications. Thermal expansion of the casing and gears reduces the gap in the pump, which can also lead to increased wear and, in extreme cases, pump failure.

Despite the best precautions taken, gear pumps often wear gears, housings, and bearings over time. As the gap increases, the efficiency will gradually decrease, and the flow slip will also increase: the pumped fluid leaks from the discharge port back to the suction side. Flow slip is directly proportional to the cube of the gap between the gear teeth and the bushing. Therefore, in practice, the effect of wear is very small until the critical point is reached, which will cause a rapid decline in performance.

The gear pump continues to withstand back pressure. If it is blocked downstream, it will continue to pressurize the system until the pump, piping, or other equipment fails. Although most gear pumps are equipped with safety valves for this reason, it is always recommended to install safety valves elsewhere in the system to protect downstream equipment.

The lower speed, larger clearance and larger internal volume of the internal gear pump make them more suitable for shear sensitive liquids such as food, paint and soap than the external gear design. When hygiene is important, internal gear pumps are also preferred because of their mechanical simplicity and the fact that they are easy to disassemble, clean and reassemble.

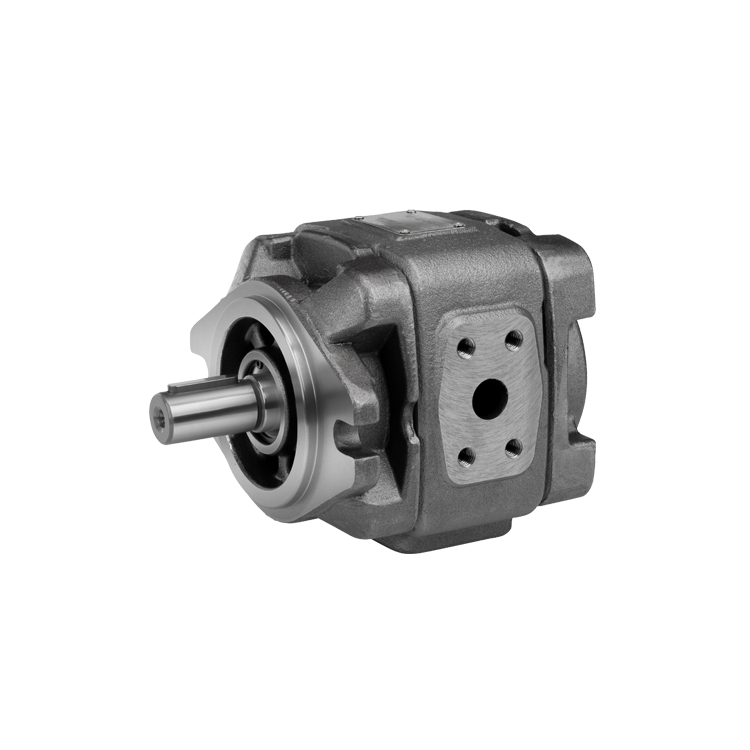

Zhejiang Yongling Hydraulic Machine Co , Ltd . is a professional China manufacturer and supplier of internal gear pumps. YLH series internal gear pump products have the advantages of high working pressure, high volumetric efficiency, low pressure pulsation and so on. Our products are widely used in cutting, plastics, forging, engineering, leather, pressure, metallurgy, agriculture, transportation machinery and machine tools, hydraulic stations, automatic production lines and other fields. Welcome to consult and purchase: https://www.china-vanepump.com/product/internal-gear-pumps/