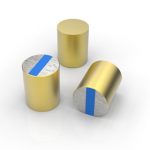

Magnet Assembly

Our magnet assembly includes hundreds of standard magnetic assemblies that can be used in workshops, schools, homes, supermarkets, offices, precast plants, etc.

Applications of Magnetic Assembly

Our magnetic assembly is widely used for Magnetic Formwork System, Lifting/ Holding, Organizing, Separating, and Office Application.

l Magnetic Assembly for Organizing

By using different colors it became easier to categorize objects according to certain criteria—this is what these products are about.

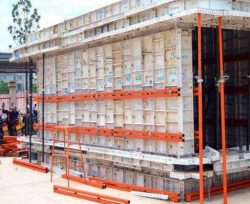

l Magnetic Assembly for Magnetic Formwork System

Precast factories produce each ‘component’ of a building such as walls, floors, stairs, roofs and then construction workers put these components together to have a building.

l Magnetic Assembly for Lifting/Holding

Most of our pot magnets, channel magnets —these series names are more about their shapes than applications — were well designed so that the magnetic energy which was evenly distribute.

l Magnetic Assembly for Office Supplies

Most of our office magnets provide great assistance especially when you want to, for instance, attach a blueprint on the white board, hang posters for an event.

Large Selection of Magnetic Assemblies for Various Applications

Our products include hundreds of standard magnetic assemblies that can be used in workshops, schools, homes, supermarkets, offices, precast plants, etc. We are a professional magnetic assembly manufacturer and we mainly supply to business customers with magnetic products in various shapes, sizes. Our neodymium pot magnet series, hook magnets, shuttering magnet series, rubber coated pot magnets, channel magnets are all our “hot sellers”.

Custom Manufacturing Magnet Assembly

We have equipment for metal processing that enables us to produce precision-machined metal parts or mould-made punching parts at the requested size & shape; in our rubber coating workshop we use EPDM, TPV to produce coated parts. What’s more important is that we are experienced at magnetic circuit design especially on magnetic assemblies of the magnet and metal parts. Combined with the aid of finite element software we can fully exploit magnetic field strength and come up with an optimized structure design.

FAQs about Magnet Assembly

What is Magnet Assembly?

Magnetic assemblies are components or devices or systems that combine magnetic & non-magnetic materials with the aim of high magnetic field and cost reduction. They are used for a huge variety of applications including precast, automation, holding, green energy, tools, etc.

What affects the strength of a magnet?

The maximum energy product of a magnet is measured in Mega Gauss Oersteds (MGOe). This is the primary indicator of a magnet’s “strength”. In general, the higher the maximum energy product value, the greater the magnetic field the magnet will generate in a particular application.

How many types of magnets are there?

Three types of Magnets. The three types of magnets are temporary, permanent, and electromagnets. Magnets are categorized by their source of magnetism. Temporary magnets become magnetized in the presence of a magnetic field.

How long will a magnet stay magnetized?

Sintered Nd-Fe-B magnets will remain magnetized indefinitely. They experience a minuscule reduction in flux density over time. As long as their physical properties remain intact, neodymium magnets will likely lose less than1% of their flux density over 100 years.