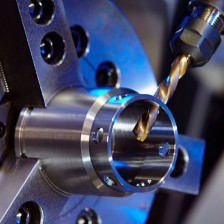

Nitrile glove production line

Introduction of household gloves production line:

The full dipping production line for household gloves adopts continuous production method and direct dipping method, with uniform film formation and bright color. Various models and specifications can be produced online at the same time. The length of the production line is 60 meters, 80 meters, 100 meters and other specifications, with a high degree of automation , Large output, automatic demoulding can be configured, and the length of the production line can also be designed and installed according to the customer’s production site.

Features:

1. The machine can carry out humanized design according to the curing and molding process of various materials (natural rubber, nitrile rubber, PVC, PC). The process is reasonable and the glue replenishing system is automatically balanced, so that the product is stable, the coating thickness is uniform, the length is uniform, and there is no sag It has the characteristics of uniform temperature, high output, easy and simple demoulding.

2. The oven adopts the principle of hot air circulation to make the internal temperature of the oven uniform, and high-performance thermal insulation materials are used to effectively ensure that the temperature does not lose, thereby improving the use of the thermal efficiency of the machine. Accuracy of temperature control, thereby improving the qualification rate of products.

3. The specially designed elastic piston type mold connecting device makes it easy to replace the mold, and there is no mold drop phenomenon.Specifications of household pvc/nitrile/latex production line: