Preconditions for a Medical Device Quality Management System

With strict regulatory oversight from certification and regulatory bodies, it has become mandatory to develop an effective quality management system that can ensure processes and their applications are able to consistently produce products and services that meet pre-determined requirement.. So, what are the key attributes to consider when creating a compliant, conformant, and effective medical device Quality Management System (QMS)?

Companies offering services or products to the medical device industry have applicable standards and regulations that define minimum requirements for the processes and outputs required to be documented, implemented, mantained, and often continually improve under their quality management systems. In order for companies to create a compliant, conformant, and effective quality management system the design and development of this system has to consider the following key aspects:

Identify Applicable Activities: The first step of the design and development process of a quality management system is for the organization to understand and identify the activities the organization will perform. Our industry, over time, has created eight categories of activities that should be considered and they include the following: design, development, manufacture / manufacturing, installation, service, sales, distribution, warehouse / warehousing or storage. The organization therefore should evaluate the overall purpose of the business and identify which of these activities they will be performing.

Identify Applicable Requirements: Once the list of activities the organization will be performing is completed, then the organization shall review the standards and regulations that will apply to the specific product(s) or service(s) that will be offered. In the medical device industry, the applicable requirements to a medical device company and more specifically to the quality management system is directly related to the level of risk of the products or services that the company will put on the market. At the same time, the jurisdiction where the company will have their place of business as well as where they will offer their products or services is also a key aspect to consider. In general, international standards are universal but regulations are country specific. For example, in the United States of America, manufacturers of finished medical devices must comply with Quality System Regulations (QSR) as defined under the US Code of Federal Regulation; FDA Quality System Regulations. QMS need to comply with the requirements of Once these requirements are identified, then a detail review of these requirements shall be performed to determine what processes need to be created to support a compliant, conformant, and effective quality management system.

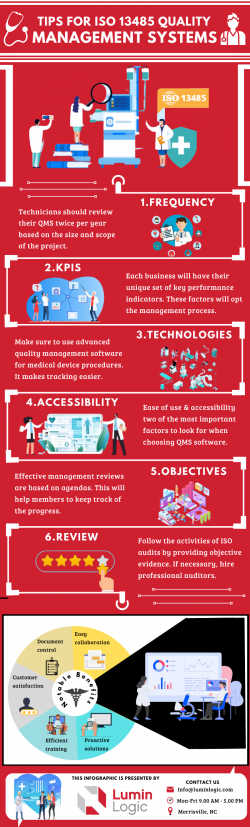

Resource Evaluation: Once the processes required for the QMS are identified, the organization shall understand their human resources. How many employees will be supporting each process? This evaluation shall be performed as early as possible because the specific design of the documented procedures, work instructions, and as applicable, the forms that produce the process outputs to ensure effectiveness of implementation of the processes shall be created in line with available human resources. If an organization is small, the organization would be unable to allocate multiple employees to support a process and therefore the process shall be design to be lean, with limited layers of oversight, and with a limited number of key process indicators (KPIs) as outputs to be monitored. If an organization is large, then processes can be design with a higher level of complexity, requiring several layers of oversight, and generating multiple KPIs as outputs to be monitored.

Design and Implementation of KPIs: KPI implementation is a fundamental tool companies have to monitor, maintain, and continually improve their QMS. If design appropriately, these indicators will provide a clear understanding to the organization’s management team of the level of effectiveness of implementation of the processes under the company’s QMS. This evaluation shall be performed taking into account the business model and related activities being performed, the products and services provided, and the applicable statutory and regulatory requirements. KPIs shall provide top management with information that can be evaluated to determine the level of effectiveness of implementation of the process. This information would also be linked to the level of quality of the products or services being provided.

In summary, the design and development QMS of a company offering products or services to the medical device industry shall be a strategic process to ensure that the output is a conformant, compliant, and effective QMS that is able to provide a system of control that ensures that the processes or services being provided consistently meet requirements.

If your organization needs assistance on the process of designing, developing, documenting, implementing, maintaining, evaluating, or improving a QMS you can contact our experts today! www.mdrconsultants.com.