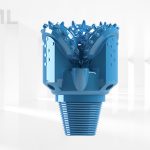

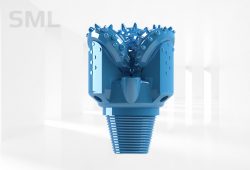

ROCK REAMER

There is no fixed tooth shape and bearing for the rock reamer, so it is necessary to select appropriate tooth shape and bearing structure according to different stratum structure. It adopts the palm back tilt, cold inlaid anti – ruin gold design, with the roller anti-peeling structure, mainly to prevent the roller falling off after the roller bearing is damaged, resulting in the accident in the hole. The roller reamer is suitable for horizontal directional drilling construction, with high design strength, good wear resistance, long service life and good safety performance. The reaming size is 220~1600mm.

Types Of Rock River Reamer

Roller Cone Reamer

It means that the teeth using the roller are milled teeth, that is, the teeth milled out on the matrix of the roller, whose wear resistance is relatively poor. In order to improve its wear resistance, it is often coated with a hard alloy layer.

What Are Rock Reamer Made Of?

01

The Structure Of The Rock Reamer Is Shown In The Figure

The rock reamer mostly uses the single tooth palm of the cone bit and the cone as one cutting edge,

02

With The Number Of Cutting Edges At Least 3

The cone reamer is composed of a rear centering plate, a rear baffle.

03

A Mandrel

A front baffle, a front centering ring, a front centering plate, a cone, and a tooth palm.

04

The Reamer Uses Welding Process To Connect And Fix The Components.

In the process of hole reaming, the screw drill provides torque and the drill provides tension.

https://www.sml-pdcbit.com/products/rock-reamer/