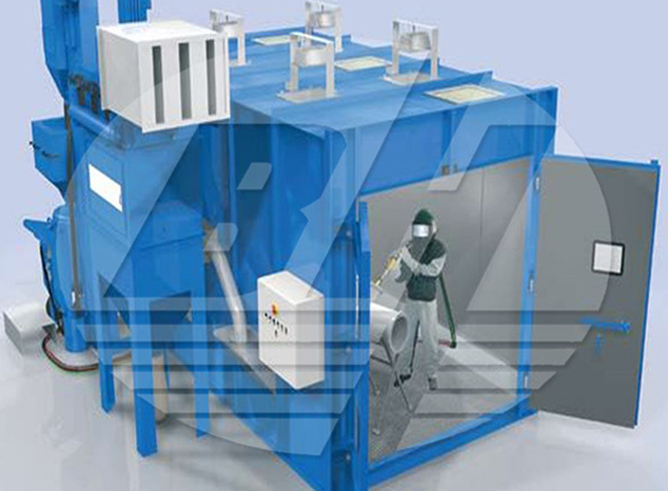

Sand Blasting Room

Sand blasting room is special equipment designed to meet specific process requirements. Through shot blast cleaning, the dirt, oxide scale, welding slag and waste paint on the surface of the complex workpiece can be removed. After shot peening, the surface of the workpiece can be smooth, the internal stress of the workpiece can be reduced, the surface of the workpiece can be strengthened, and the purpose of improving the surface and internal quality of the workpiece can be achieved. For the sandblasting equipment price, please get a quote.

Specification of Sand Blasting Room

Item Type

Q0250A

Q0250A-Ⅱ

Q0250A-Ⅱ-LX

Volume of in-tank (m3)

0.52

0.7

0.82

Air pressure (Mpa)

0.5

0.67

0.8

Emitted dose (caliber=φ10)(kg/h)

1 gun

1800-2280

1 gun

1800-2280

1 gun

1800-2280

2 guns

3600-4560

2 guns

3600-4560

2 guns

3600-4560

Air consumption (m3/min)

1 gun

6.1

1 gun

6.1

1 gun

6.1

2 guns

12.0

2 guns

12.0

2 guns

12.0

Length of blasting pipe (mm)

15000 (2pcs)

15000 (2pcs)

15000 (2pcs)

Dimension (mm)

1036*812*1860

1120*902*1890

1088*812*2060

Weight (kg)

396

500

690

Sand Blasting Room Video

Advantages of Sandblasting Safety Equipment

Durable components that needs very little maintenance cost

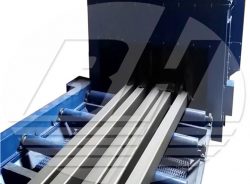

Screw conveyor system of the air powered sandblaster can recover as quick and much as your need

No limits as regards to room dimension

Recovery hopper floor layout as tailored

Storage hopper capacity of sand blasting chamber is large to allow long sandblasting autonomy

Powerful dust collector that keeps the environment free of dust and fine particles, and that increases significantly the equipment lifespan

Abrasive recovery system with adjustable separators that take charge of a wide variety of abrasive and media sizes

Application of Sand Blasting Room

The best sandblasting equipment uses manual shot blasting to remove surface rust. The surface finish and roughness of the cleaned workpiece meet the customer’s request. Removal of dirt, oxide scale, welding slag and waste paint on the surface of complex workpiece can make the surface of workpiece smooth, reduce the internal stress of workpiece and strengthen the surface of workpiece in order to improve the adhesion and anti-corrosion ability of paint.

Equipment Components of Sand Blasting Room

This large sandblaster for sale is a special flat trolley shot peening equipment. Sandblasting equipment and supplies consist of a shot peening room, flat trolley conveying system, shot peening pot, pneumatic scraper system, screw conveyor, elevator, separator, shot-abrasive control system, lighting system, dust removal system and electric control system, etc.

https://www.qdbhmachinery.com/products/sand-blasting-room.html