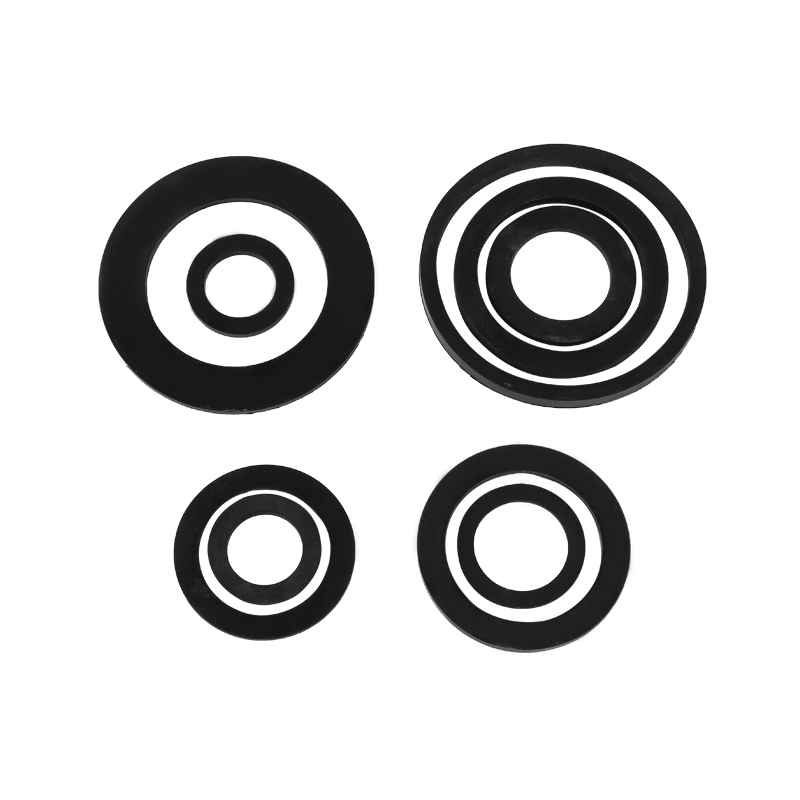

Secure Your Machinery with Skeleton Oil Seals

In the world of industrial machinery, maintaining optimal performance and preventing any potential damage is of utmost importance. That’s where skeleton oil seals come into play. These small but mighty components play a crucial role in ensuring the smooth operation of machinery by preventing oil leakage. In this blog, we will explore what skeleton oil seals are and why they are essential in various industries. What are Skeleton Oil Seals? Skeleton oil seals are mechanical devices designed to prevent oil leakage in industrial machines. They consist of two main parts: the metal case and the elastomer lip. The metal case provides structural support and rigidity, while the elastomer lip serves as the sealing element that prevents oil from escaping or entering areas where it shouldn’t be. Importance of Skeleton Oil Seals 1. Protection against Oil Leakage: The primary function of skeleton oil seals is to prevent oil leakage from machinery. By creating a tight seal between the moving parts, these seals ensure that the lubricating oil stays inside the bearing housing where it is needed. This helps to maintain proper lubrication and prevents costly damage to the machinery due to oil leakage. 2. Contamination Prevention: Skeleton oil seals not only keep oil from escaping but also prevent contaminants such as dust, dirt, water, and other external particles from entering the bearings. This contamination prevention is essential for the longevity and efficiency of the machinery, as foreign particles can hamper the smooth operation of the moving parts. 3. Temperature and Pressure Resistance: Skeleton oil seals are designed to withstand high temperatures and pressures commonly found in industrial applications. They are made from durable materials that can withstand extreme conditions, ensuring their effectiveness and longevity in harsh operating environments. Application of Skeleton Oil Seals Skeleton oil seals find applications in various industries, including automotive, manufacturing, agriculture, and aerospace. They are commonly used in engines, gearboxes, pumps, and other rotating machinery where preventing oil leakage is critical for efficient operation. Conclusion In conclusion, skeleton oil seals serve a crucial function in preventing oil leakage and contamination in industrial machinery. By creating a reliable barrier between the moving parts and the surrounding environment, these seals help ensure the smooth operation and longevity of the machinery. So, if you want to secure your machinery and protect it from potential damage, skeleton oil seals are a small investment that makes a big difference.