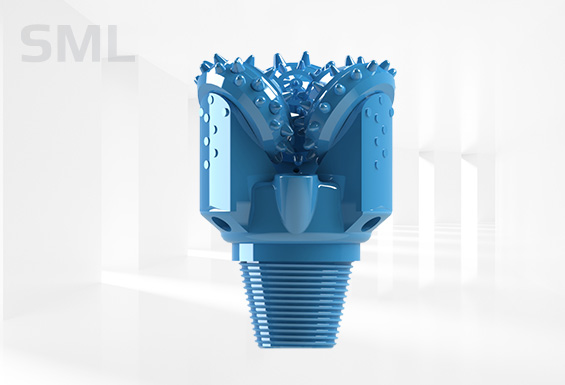

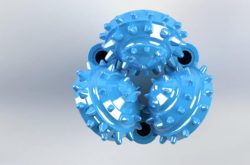

TRICONE BIT

Adopt high-precision metal seal. The metal seal consists of a pair of well-designed and processed metal seal rings as the axial dynamic seal of the bearing, and two highly elastic rubber energy supply rings are respectively located in the tooth palm and roller seal areas as static seals. A metal ring sealing surface is always in good contact.

The use of all-rubber oil storage bag that can limit the pressure difference and prevent drilling fluid from entering the lubrication system provides a good lubrication guarantee for the bearing system.

A new type of grease that can withstand 250°C high temperature and wear resistance is used.

Types Of TCI Tricone Bit

TCI Tricone Bit

TCI Bit

The insert drill adopts high-strength and high-toughness carbide teeth, and the optimized design of the number of tooth rows, the number of teeth, the exposed tooth height and the unique alloy tooth shape give full play to the high wear resistance and excellent cutting ability of the insert drill.

Steel Tooth Bit

The tooth surface of the nilled-tooth drill is coated with new wear-resistant materials, which improves the life of the cutting teeth of the drill while maintaining the high ROP of the milled-tooth drill.

What Are Tricone Bits Made Of?

01

Bit Body

There are three tooth palms assembled and welded together, and there is a connecting thread on the upper part.

02

Bearings And Their Oil Storage Seals

There are three tooth palms assembled and welded together

03

Cone

A conical metal body composed of a cone body and teeth. There are two types of tooth: milled tooth and inset tooth

04

Nozzle

There are three tooth palms assembled and welded together

https://www.sml-pdcbit.com/products/tricone-bit/