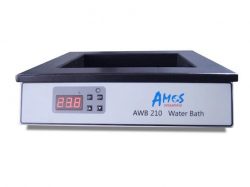

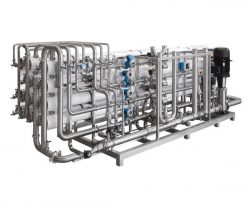

Water For Injection System (WFI)

BIOCELL water for injection equipment adopts advanced three-stage separation process of steam and water, and the quality of produced water meets the standards of Chinese, American and European Pharmacopoeia, GMP, FDA and other certification requirements; Humanized design, modular installation, small floor area, stable operation, one button start, simple operation and maintenance, high efficiency and energy saving.

DIFFERENT TYPES OF WFI SYSTEM

Multi-Effect Distiller

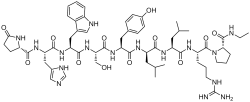

The multi effect distilled water machine is designed and manufactured according to the industry standard YY0229 Multi effect Distilled Water Machine. All parts are made of 304 and 316L stainless steel. The distilled water produced is of high purity and pyrogen free, and fully complies with the quality indicators of water for injection in the Pharmacopoeia of the People’s Republic of China (2020). It is the ideal equipment for manufacturers of various blood products, injections, infusion, biological antibacterial and other drugs and manufacturers of drinking distilled water.

Read More

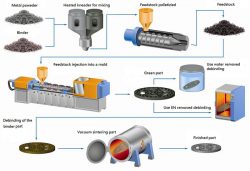

WHAT IS THE WORKING PRINCIPLE OF WFI SYSTEM?

The system has low investment cost, low operation and energy consumption, and can operate continuously and dynamically. Under the condition of low temperature storage and turbulence, it can effectively control the microbial breeding risk of the whole system, and can realize large-scale water supply.

WATER FOR INJECTION SYSTEM SOLUTIONS

FIRST

WFI by Distillation

At present, water for injection (WFI) is mainly obtained by the following thermal distillation methods:

Multiple Effect Distillation Units

Single Effect Distillation Units

Single effect or multi effect thermal distillation is the most popular production method of water for injection (WFI). The main advantages of this method are simple design, no moving parts are used in the WFI water generation process, so it has reliability. Since the process is carried out at high temperature, the method has full confidence in the microbial purity of the water obtained.

SECOND

Cold WFI by Membrane Methods

When using the whole membrane method to prepare cold water for injection, special attention should be paid to the design of regular sanitary treatment of the system. Cold process is always more susceptible to microbial contamination than traditional hot distillation. The cold WFI power generation equipment shall be cleaned regularly, preferably by thermal disinfection.

https://www.biocell-pharma.com/products/wfi-water-for-injection-system/