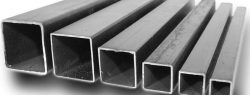

Aluminum tube profile series

Aluminum Extrusion Tube

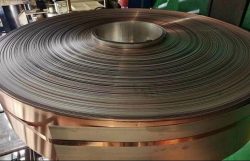

The extrusion process shapes aluminum by heating the billet and forcing it through the forming openings in the die, producing up to 5 kilometers of extruded product from a single billet. After exiting the extrusion process, the tube is shaped to the same shape as the die opening and then coiled. Depending on the product specifications, coatings such as zinc and solder can be applied to enhance the tube’s performance.

Extruded tubes are manufactured with high precision and very low tolerances to meet specific customer requirements.

Extruded aluminum tube applications

Transportation industry

Marine industry

Solar and Renewable Energy

Building and construction (commercial and residential)

Military and Defense

Electrical bus conductors

Compressed Gas Storage