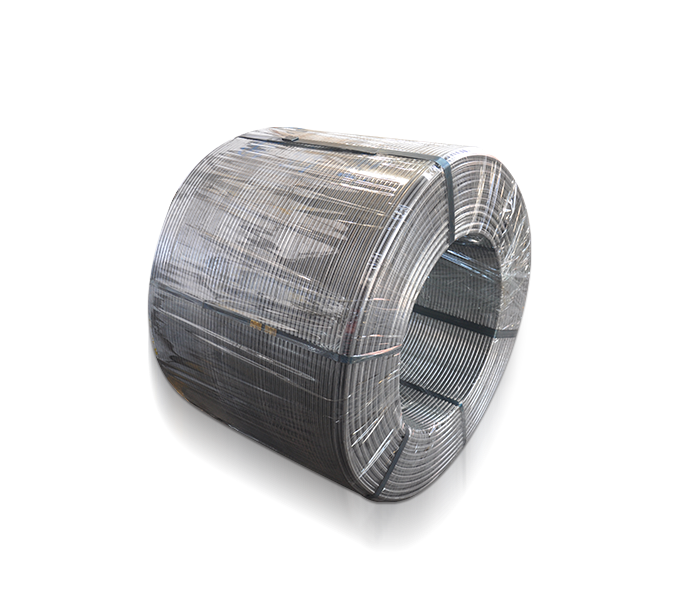

Custom Ca-Fe Cored Wire

Calcium iron cored wire is made by mixing calcium and iron powder in a certain proportion.

Calcium iron cored wire is composed of 25-35% calcium particles, the rest of which is the mixture of iron powder. The cored wire is made of strip steel. The general specifications are mainly calcium 30 and calcium 40. The domestic and foreign iron and steel enterprises usually use calcium iron-clad wire for calcium treatment of low carbon, ultra-low carbon, low silicon steel, and pure steel with strict requirements on the morphology and quantity of inclusions.

Advantages Of Cafe Cored Wire

1. Avoid formulating the long strip of sulfide inclusion, improve the anisotropy of steel.

2. Being fastly feed into the molten steel by wire feeding machine, melt in the depth of molten steel, relieve the nozzle clogging, to play the role of deoxidization, desulfurization, and eliminating inclusion.

3. Finely adjust the composition, increase the yield of metal and rare earth elements, ensure the stability of components. Reduce the number of noble metal elements and refining costs.