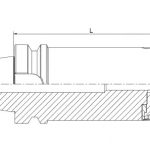

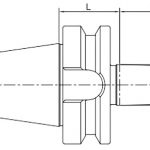

DIN 69893 (ISO 12164) HSK-F TOOL HOLDERS

BRIGHT-TOOLS offers premium DIN 69893 (ISO 12164) HSK-F tool holders, designed for high-speed cutting applications. Our HSK-F tool holders provide exceptional stability and cutting accuracy, ensuring superior performance even under the most demanding conditions. With BRIGHT-TOOLS HSK-F tool holders, customers can achieve greater precision, efficiency, and profitability in their machining processes.

WHAT TYPES OF MACHINES ARE DIN 69893 (ISO 12164) HSK-F TOOL HOLDERS SUITABLE FOR?

HSK-F tool holders are suitable for high-speed spindles in CNC machines. These tool holders are specifically designed for applications that require high-performance, high-precision, and high-speed cutting operations. HSK-F tool holders provide optimal stability and accuracy during machining processes, making them suitable for various machines such as milling machines, lathes, grinding machines, and drilling machines. The HSK-F system ensures effective transmission of torque, enhanced cooling capabilities, and reduced tool vibration, resulting in improved machining precision and surface finish.

HOW TO ENSURE PROPER MAINTENANCE AND CARE FOR DIN 69893 (ISO 12164) HSK-F TOOL HOLDERS?

To ensure proper maintenance and care for HSK-F tool holders, follow these steps:

1. Regularly inspect the tool holders for any signs of wear, damage, or contamination.

2. Clean the tool holders with a non-abrasive solvent after each use to remove chips, dust, and dirt.

3. Lubricate the tool holders with a recommended oil or grease to prevent rust and maintain smooth operation.

4. Store the tool holders in a clean, dry, and climate-controlled environment to protect them from moisture and temperature fluctuations.

5. Follow manufacturer recommendations for tightening and loosening the tool holders to prevent overtightening or undertightening.